Table of Contents

ToggleI. Introduction

Pneumatic fittings are essential components in pneumatic systems, facilitating the flow of compressed air and impacting overall system performance.

When diving into the world of pneumatic systems, it’s essential to grasp the significance of pneumatic fittings. These small yet vital components ensure that air flows seamlessly through your equipment, affecting overall performance. As I explore the details in this guide, I will help you navigate the complex landscape of pneumatic fittings, ensuring you find the best solutions for your needs.

II. Pneumatic vs. Hydraulic Fittings: Key Differences

The primary difference between pneumatic and hydraulic fittings lies in the type of fluid they handle, with pneumatic fittings designed for air and hydraulic fittings for liquids.

The first thing to consider is the type of fluid each fitting is designed for:

| Feature | Pneumatic Fittings | Hydraulic Fittings |

|---|---|---|

| Fluid Type | Compressed air | Hydraulic oil (liquid) |

| Pressure Rating | Generally up to 150 psi | Often from 1,500 to over 10,000 psi |

| Material | Typically lighter materials (plastic, aluminum, brass, stainless steel) | Durable materials (steel, stainless steel) |

| Connection Type | Push-to-connect, quick-disconnect | Threaded, flanged |

These differences mean that pneumatic fittings operate at lower pressures and are often lighter and easier to install than their hydraulic counterparts.

III. Types of Pneumatic Fittings

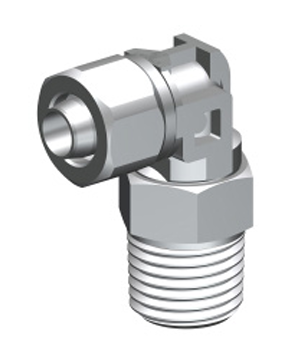

Common types of pneumatic fittings include push-to-connect, compression, barbed, and quick-disconnect fittings, each serving specific applications.

Familiarizing yourself with the various types of pneumatic fittings will empower you to choose the right one for your application. Here are some common types of pneumatic fittings:

- Push-to-Connect Fittings: Allow quick assembly without tools, perfect for flexible installations.

- Compression Fittings: Provide secure connections and are often used in applications requiring high reliability.

- Barbed Fittings: Great for connecting tubing; they rely on friction to maintain a tight seal.

- Quick-Disconnect Couplings: Ideal for easy attachment and detachment, facilitating rapid equipment changes.

| Type | Description | Ideal Use Case |

|---|---|---|

| Push-to-Connect | Quick assembly, tool-free | General applications |

| Compression | Secure and reliable connections | High-pressure systems |

| Barbed | Friction-based seal | Tubing connections |

| Quick-Disconnect | Fast coupling and uncoupling | Equipment maintenance |

IV. Selecting the Right Pneumatic Fitting

Choosing the right pneumatic fitting involves considering pressure requirements, compatibility, environmental factors, and flow rates.

When selecting a pneumatic fitting, I consider:

- Pressure Requirements: Ensure the fitting can handle the maximum pressure in your system.

- Compatibility with Tubing: The fitting must match the tubing material and size.

- Environmental Factors: Assess the operating environment, including temperature and exposure to corrosive elements.

- Flow Rate Considerations: The fitting should support the required flow rate without causing pressure drops.

V. Materials Used in Pneumatic Fittings

Common materials for pneumatic fittings include brass, stainless steel, plastic, and aluminum, each offering unique benefits for different applications.

The most common materials for pneumatic fittings include:

- Brass: Durable and resistant to corrosion; often used in general applications.

- Stainless Steel: Ideal for high-pressure and corrosive environments.

- Plastic (Nylon, Polyurethane, PBT): Lightweight and resistant to corrosion; suitable for lower-pressure applications.

- Aluminum: Lightweight and strong; often used in aerospace applications.

Each material has its own advantages and limitations, and I carefully evaluate my application needs to choose the best option.

VI. Ensuring Proper Installation and Leak Prevention

Proper installation techniques and regular maintenance are essential for preventing leaks and ensuring the longevity of pneumatic fittings.

To ensure a leak-free installation:

- Follow Assembly Techniques: Ensure fittings are assembled correctly; over-tightening can damage components.

- Use Thread Sealants: Apply appropriate sealants to threaded connections for added leak protection.

- Regular Maintenance: I perform routine inspections to identify wear and tear early, prolonging the fitting’s life.

VII. Safety Considerations for Pneumatic Systems

Safety in pneumatic systems involves understanding pressure ratings, implementing fail-safe mechanisms, and using personal protective equipment.

I always prioritize safety by:

- Understanding Pressure Ratings: Ensure all components are rated for the maximum operating pressure.

- Implementing Fail-Safe Mechanisms: Design systems that include relief valves to prevent over-pressurization.

- Using Personal Protective Equipment: I recommend using safety goggles and gloves during installation and maintenance.

VIII. Cost Considerations

Balancing cost with quality is crucial when selecting pneumatic fittings, as initial savings can lead to higher long-term costs if quality is compromised.

When considering the cost of pneumatic fittings, I always keep in mind:

- Initial Investment vs. Long-Term Durability: While cheaper fittings might seem attractive initially, I’ve found that investing in higher-quality components often leads to lower total costs over time due to increased reliability and reduced maintenance needs.

- Quality-Budget Balance: It’s essential to find the sweet spot between quality and budget constraints. I recommend prioritizing critical components where failure could lead to significant downtime or safety issues.

- Bulk Purchasing Options: For large-scale projects or ongoing needs, I’ve often found that negotiating bulk purchase agreements with suppliers can lead to substantial cost savings.

Here’s a simple cost-benefit analysis I use when evaluating fitting options:

| Factor | Economy Fittings | Premium Fittings |

|---|---|---|

| Initial Cost | Lower | Higher |

| Lifespan | Shorter | Longer |

| Maintenance Frequency | Higher | Lower |

| Reliability | Lower | Higher |

| Long-term Cost | Can be higher due to replacements | Often lower due to durability |

IX. Customization and Special Requirements

For unique applications, collaborating with manufacturers to develop custom pneumatic fittings can provide optimal solutions.

In my experience, off-the-shelf fittings don’t always meet specific needs. Here’s how I approach customization:

- Collaboration with Manufacturers: I engage directly with fitting manufacturers to discuss unique requirements. Many are willing to modify existing designs or create entirely new solutions.

- Adapting Fittings for Specific Applications: Sometimes, a combination of standard fittings with custom adaptors can solve complex connection issues. I always explore these options before committing to fully custom solutions.

- Material Selection for Unique Environments: For extreme conditions (high temperature, corrosive atmospheres), I work with suppliers to select or develop materials that can withstand these challenges.

- Prototyping and Testing: For critical applications, I always recommend prototyping and rigorous testing of custom fittings before full-scale implementation.

X. Conclusion

Selecting the right pneumatic fittings is essential for the efficiency, safety, and longevity of your pneumatic system.

As we’ve explored the world of pneumatic fittings, it’s clear that selecting the right components is crucial for the efficiency, safety, and longevity of your pneumatic system. Let’s recap the key points:

- Understanding the differences between pneumatic and hydraulic fittings is fundamental.

- Choosing the right type and material for your fittings can significantly impact system performance.

- Proper installation and maintenance are crucial for preventing leaks and ensuring longevity.

- Safety should always be a top priority in pneumatic system design and operation.

- Balancing cost with quality often leads to better long-term outcomes.

- For unique applications, don’t hesitate to explore custom solutions.

I encourage you to leverage this knowledge when selecting a pneumatic fittings supplier. Look for partners who demonstrate expertise in these areas and are willing to provide guidance tailored to your specific needs.

Although this article provides a comprehensive overview, pneumatic systems can be complex. Don’t hesitate to contact us for your specific applications, especially for critical or high-performance systems.