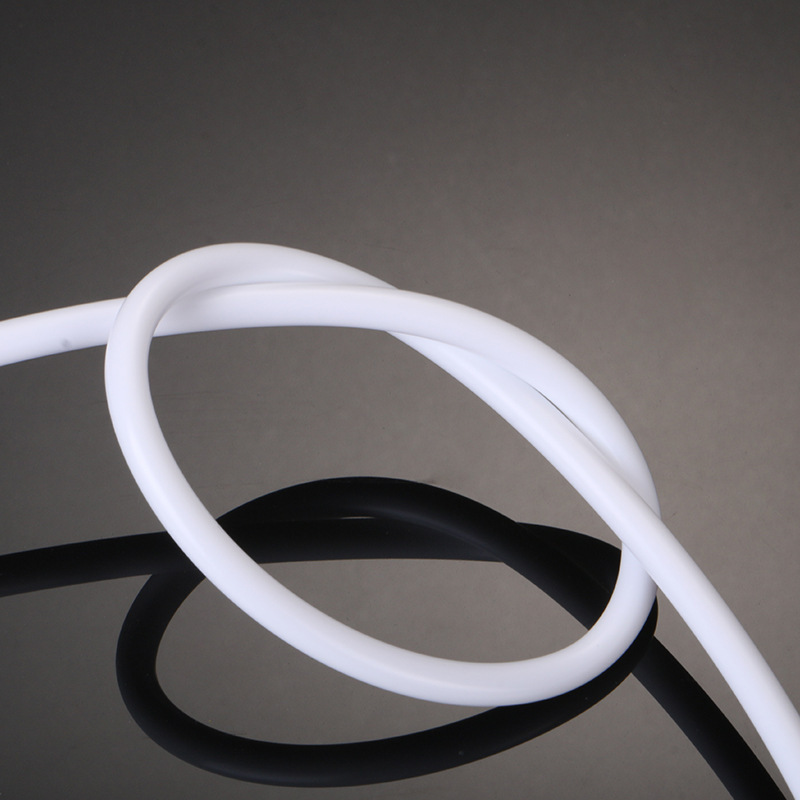

I’ve specified, installed, and troubleshot miles of pneumatic tubing in OEM machines and plant utility air. When weight, chemical exposure, and budget are on my mind, polyethylene (PE) routinely earns a spot on the BOM. It’s not the right answer for every dynamic axis or high-heat zone—but in low-to-medium pressure circuits, manifolds, and distributed air drops, PE gives me dependable performance without inflating cost or maintenance risk.

Polyethylene pneumatic tubing offers a strong mix of low weight, excellent chemical resistance, and good flexibility at a very attractive cost. In my experience, PE performs well in low-to-medium pressure control circuits, provides clean internal surfaces that help preserve air quality, and routes easily in compact equipment. Observe typical operating ranges around -20 to 150°F (-29 to 66°C) and working pressures from roughly 60 to 160 psi depending on grade and wall, and avoid high-heat, high-load, or high-movement zones to mitigate creep and aging.

In the sections below, I’ll break down how PE behaves in real-world pneumatic systems—chemical resistance and routing, pressure/temperature envelopes, cost-versus-reliability trade-offs, and clear red flags where I avoid PE due to creep, UV, or thermal aging risks. I’ll also include side-by-side comparisons to help you choose between PE, PU, nylon, and PTFE for each circuit in your machine.

Table of Contents

ToggleHow does PE perform in chemical resistance and lightweight routing on my equipment?

Chemical compatibility and air quality

- Broad-spectrum resistance: PE handles many acids, bases, salt solutions, alcohols, and common cleaning agents exceptionally well. This is why I lean on PE for washdown-adjacent manifolds, analyzer air lines, and utility drops near chemicals.

- Low moisture uptake: PE’s low moisture absorption and good barrier properties help keep entrained water and contaminants from permeating the line, stabilizing downstream FRL and regulator performance over time.

- Stress cracking: If environmental stress cracking (ESC) is a concern (e.g., surfactants, certain hydrocarbons), specifying the right grade matters. LLDPE and MDPE/HDPE with better ESCR ratings outlast generic LDPE in harsh chem zones. I always cross-check supplier chemical charts for specific cleaners and solvents used on the floor.

Lightweight, flexible routing

- Reduced mass on moving axes: For light pick-and-place or modestly dynamic tooling, PE’s low density reduces inertial load versus nylon, and dramatically versus metal tube. That can let me downsize carriers or avoid counterbalances.

- Tight but controlled bend radii: PE’s flexibility supports compact routing without kinking when the minimum bend radius is respected. I avoid cable ties that pinch; I use smooth clamps and guides.

- Smooth bore, lower ΔP: The inner surface is typically smooth; combined with appropriate bore size, this helps reduce pressure drop. In large distributed networks, smoother tube plus leak-minimized push-to-connect (PTC) fittings adds up to compressor energy savings.

Fittings and sealing tips

- Push-to-connect fittings with properly deburred cuts work best. I use square cuts, verify full collet engagement, and perform tug tests.

- For chemical splash zones, nickel-plated brass or stainless PTC bodies plus EPDM or FKM seals (per chemical list) increase longevity.

- Use strain reliefs near actuators or tools; PE is tougher than PVC but not as cut-resistant as PU.

What pressure limits and temperature ranges should I observe with PE in my lines?

PE working limits vary with density (LDPE, LLDPE, MDPE, HDPE), wall thickness, and temperature. Here’s how I frame it in design reviews:

Practical envelopes I use in industry

- Working pressure: About 60–160 psi (4–11 bar) covers most PE pneumatic tubing SKUs used in control circuits; always check the data sheet for your exact OD/ID and grade. Burst pressure is typically ≥3x working pressure.

- Temperature: -20 to 150°F (-29 to 66°C) is a solid rule-of-thumb for standard grades. Cold toughness is good; at the high end, soften and creep accelerate above ~140°F (60°C).

- De-rate for heat: At elevated temperatures, I downrate allowable pressure significantly, and I avoid proximity to motors, dryers, ovens, and radiant heaters unless shielded.

Comparison table: typical tubing choices

| Property | PE (LLDPE/HDPE) | PU (Ether-based) | Nylon (PA12) | PTFE |

|---|---|---|---|---|

| Typical working pressure (1/4 in OD) | ~60–160 psi | ~100–200+ psi | ~200–350+ psi | ~250–500+ psi |

| Temperature range (approx.) | -20 to 150°F | -40 to 165°F | -40 to 200°F | -100 to 500°F |

| Flexibility (dynamic) | Good (static to light dynamic) | Excellent (dynamic) | Moderate | Low (kink-resistant but stiff) |

| Chemical resistance | Excellent to many acids/bases; watch ESC | Very good; watch hydrocarbons | Good; some chemicals limit | Outstanding |

| Cost | Lowest | Low–Medium | Medium | High |

Note: Always verify manufacturer ratings for the exact product.

Flow and Cv considerations

- For control lines, PE’s smooth bore helps maintain Cv predictions. I still model pressure drop with actual ID and the longest run plus fittings. Keep velocity below ~20–30 ft/s in air to minimize noise, erosion, and ΔP.

Can PE help me reduce costs for low-demand circuits without sacrificing reliability?

Yes—this is where PE shines for me.

Cost-to-performance sweet spot

- Material and install cost: PE is often the most cost-effective rigid polymer tube for pneumatics. It’s light, easy to cut, and needs fewer direction changes due to bendability—fewer elbows, fewer leak points.

- Network efficiency: Smooth internal surfaces and consistent IDs reduce compressor energy in large manifolds and drops when paired with good leak management (<5% plant target).

- Availability and sustainability: Broad availability, recyclable material, and color-coding options (transparent/natural, black UV-stabilized, blue, red, yellow) simplify MRO, visual tracing, and 5S.

Reliability practices I use

- Right grade, right zone: Use UV-stabilized black PE outdoors or near skylights; upgrade to HDPE/LLDPE with high ESCR where cleaners are aggressive.

- Bend radii and support: Respect minimum bend radius; use clamps every 18–24 inches on horizontals and near fittings to prevent micro-motions that loosen collets.

- Air prep: A good FRL stack (0.01–0.3 μm coalescing where valves are sensitive) plus stable dewpoint prevents internal icing and protects seals. PE doesn’t like oil swell much, but excessive compressor oil carryover can compromise seals in fittings.

Quick selection matrix (applications I routinely pick PE for)

- Panel and sensor air, pilot lines, IO-Link valve islands

- Distributed plant air drops with moderate pressures

- Food/bev and lab air where chemical wipe-down occurs (check FDA/NSF grades if needed)

- Static or lightly moving harnesses on small tooling

When should I avoid PE due to creep or aging concerns in my environment?

PE is a thermoplastic; under heat and sustained stress, it creeps. In a few scenarios, I will switch to PU, nylon, or PTFE:

Red flags and mitigations

- Elevated heat (>150°F/66°C ambient or radiant): PE softens and creep accelerates. I move to nylon or PTFE near ovens, dryers, motors, or heat exchangers—or I shield and reroute.

- High dynamic flexing or tight energy chains: Repetitive bending can notch or ovalize PE over time. Ether-based PU survives continuous motion better and resists abrasion on carriers.

- Sustained high pressure at heat: Even at 120–140°F, I de-rate heavily; for 150–200 psi circuits, nylon/PTFE is safer.

- UV/weathering outdoors without stabilization: Standard natural PE can chalk and embrittle. I specify UV-stabilized black PE or switch to PA12/metal tube; add conduit if needed.

- Chemical ESC risks (surfactants, hydrocarbons, certain solvents): If the plant uses potent detergents or fuels, I confirm ESCR data (ASTM D1693) and run a soak test. If marginal, I select PU or PTFE.

- Tight bend beyond spec or crush-prone runs: In cramped panels where bend radius cannot be respected, PU prevents kinks better; for crush or weld-spatter zones, go to metal tubing with compression fittings.

Failure modes I watch for

- Creep-induced fitting leaks: Tube OD relaxes in collets under constant hot load—periodic retorque/checks or ferruled compression fittings can help, but material change is often better.

- Surface micro-cracking from cleaners: Visual inspection during PM; replace with higher-ESCR grade or different polymer.

- Flattening at bends increasing ΔP: Re-route with larger radius or add a formed elbow.

Reference table: typical ranges and selection cues

| Attribute | PE pneumatic tubing (summary) |

|---|---|

| Working pressure (typical) | ~60–160 psi depending on grade and wall; verify datasheet |

| Burst safety factor | Commonly ≥3:1 (application-specific) |

| Temperature range | -20 to 150°F (-29 to 66°C) standard; de-rate with heat |

| Key advantages | Low cost, light weight, excellent chemical resistance, smooth bore, low moisture absorption, color options, recyclable |

| Best-fit applications | Low-to-medium pressure control circuits, panels, static/light dynamic routing, chemically aggressive wipe-down areas |

| Avoid/upgrade when | High heat, high dynamic flex, high pressure, strong UV without stabilization, ESC-prone chemicals |

Conclusion

When I need a light, clean, and economical tube for low-to-medium pressure pneumatics, polyethylene delivers. Its chemical resistance, low moisture uptake, and smooth bore keep control air stable; its flexibility simplifies routing; and its cost profile helps me hit BOM targets across large builds. I stay within the -20 to 150°F and ~60–160 psi neighborhood (per datasheet), choose ESCR-capable grades for harsh cleaners, and use UV-stabilized formulations if sunlight is a factor. For hot zones, high-duty flexing, or high-pressure demands, I shift to PU, nylon, or PTFE—but for the majority of fixed control circuits and distributed air runs, PE is a reliable, low-risk way to reduce cost without compromising performance.

Further Reading

- Engineering Toolbox – Pressure Rating of Polyethylene Pipe

- ISO – ISO 14743: Pneumatic fluid power — Push-in connectors

- SMC – Polyethylene Tubing Product Page