I. Introduction

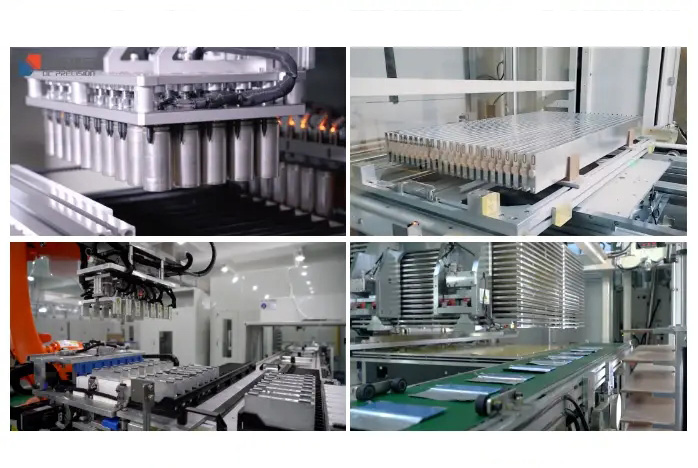

The world’s reliance on secondary batteries, such as those used in electric vehicles, renewable energy storage, and consumer electronics, has grown exponentially in recent years. As the demand for these batteries continues to rise, the importance of ensuring reliable and efficient manufacturing processes has become paramount. One critical component in the secondary battery manufacturing process is the pneuamtic push fitting, and the use of 316L stainless steel push fittings can provide significant benefits.

II. Understanding 316L Stainless Steel Push Fittings

316L stainless steel is a highly corrosion-resistant alloy that is widely used in various industrial applications, including the manufacturing of push fittings. The “L” in 316L stands for “low carbon,” which makes the material more resistant to intergranular corrosion, a common issue in stainless steel components. The key features of 316L stainless steel push lock fittings include their exceptional durability, corrosion resistance, and ability to withstand harsh environments.

III. The Role of 316L Stainless Steel Push Fittings in Secondary Battery Manufacturing

Push fittings play a crucial role in the secondary battery manufacturing process, as they are used to create secure and leak-proof connections between various components, such as battery cells, cooling systems, and electrical wiring. The reliability and performance of these connections are essential for ensuring the overall safety and efficiency of the battery production line.

A. Connecting Battery Cells with Precision

At the heart of any secondary battery lies an intricate network of interconnected cells, each playing a vital role in the overall power output and energy density of the final product. Ensuring the integrity and reliable operation of these cell-to-cell connections is a paramount concern for battery manufacturers.

Enter the 316L stainless steel push fitting – a technological marvel designed to meet the demanding requirements of secondary battery assembly. Crafted from a highly corrosion-resistant alloy, these push fittings create secure, leak-proof linkages between individual battery cells, withstanding the harsh chemical environments and extreme temperatures often encountered during the manufacturing process.

The low-carbon content of 316L stainless steel imbues these push fittings with superior resistance to intergranular corrosion, a common issue that can compromise the structural integrity of standard stainless steel components. This enhanced corrosion resistance translates to improved long-term reliability, minimizing the risk of cell-to-cell connection failures and ensuring the consistent, stable performance of the battery over its entire lifespan.

B. Integrating Cooling Systems with Confidence

Effective thermal management is a critical consideration in secondary battery manufacturing, as the efficient dissipation of heat generated during operation is essential for maintaining optimal performance and safety. Integrating the battery’s cooling systems with the core cell assembly requires a robust, leak-proof solution – a role that 316L stainless steel push fittings are uniquely positioned to fulfill.

The exceptional durability and structural integrity of these push fittings enable them to withstand the high pressures and rapid temperature fluctuations associated with the battery’s cooling infrastructure. Whether the cooling medium is a liquid or gaseous coolant, 316L stainless steel push fittings ensure a secure, leak-free connection that protects the sensitive battery cells from thermal damage and enhances the overall efficiency of the cooling system.

Furthermore, the material’s compatibility with a wide range of coolant chemistries, including those containing corrosive additives, allows battery manufacturers to tailor their cooling solutions to the specific requirements of their products without compromising the integrity of the push fitting connections.

C. Safeguarding Electrical Wiring and Monitoring Sensors

The secondary battery’s electrical wiring and monitoring sensors play a vital role in ensuring the safe and efficient operation of the entire system. Integrating these components with the battery’s core assembly requires secure, reliable connections that can withstand the harsh environmental conditions inherent to the manufacturing process.

Once again, 316L stainless steel push fittings rise to the challenge, providing a robust and corrosion-resistant solution for establishing leak-proof linkages between the battery’s electrical infrastructure and its internal components. By creating a secure seal around the wiring and sensor connections, these push fittings protect the sensitive electronics from exposure to potentially damaging fluids, gases, or contaminants, safeguarding the overall performance and reliability of the battery.

Moreover, the exceptional durability of 316L stainless steel push fittings ensures that these critical electrical connections remain intact even under the stress of vibrations, thermal fluctuations, and other physical stresses encountered during battery operation and transportation.

IV. What are The Benefits of 316L Stainless Steel Push Fittings In The Secondary Battery Manufacturing?

The strategic deployment of 316L stainless steel push fittings in the secondary battery manufacturing process unlocks a treasure trove of benefits, elevating the performance, reliability, and cost-efficiency of production workflows. These innovative connectors stand as beacons of excellence, guiding battery manufacturers towards a new era of industry-leading innovation.

A. Uncompromising Corrosion Resistance

- Crafted from a low-carbon 316L stainless steel alloy, these push fittings exhibit exceptional resistance to a wide range of corrosive chemicals, coolants, and environmental elements commonly encountered in battery production facilities.

- The superior corrosion-resistant properties of 316L stainless steel ensure the long-term integrity and leak-proof sealing of critical component connections, even under the most demanding operating conditions.

- By safeguarding the battery’s internal infrastructure from the ravages of corrosion, 316L stainless steel push fittings enhance the overall safety and reliability of the final product, instilling confidence in end-users.

B. Unparalleled Durability and Longevity

- The robust construction and high-quality materials of 316L stainless steel push fittings translate to exceptional durability, enabling them to withstand the rigors of the battery manufacturing process and the stresses of real-world operation.

- This impressive level of ruggedness contributes to a significantly extended service life, reducing the need for frequent maintenance and replacement of these crucial components.

- The enhanced longevity of 316L stainless steel push fittings directly contributes to cost savings for battery manufacturers, optimizing production efficiency and minimizing downtime.

C. Comprehensive Compatibility

- 316L stainless steel push fittings are designed to seamlessly integrate with a diverse range of materials used in secondary battery manufacturing, including various metals, plastics, and elastomers.

- This unparalleled compatibility ensures a secure and reliable connection between the different components of the battery system, fostering enhanced performance and safety.

- The versatility of these push fittings empowers battery manufacturers to explore innovative design solutions and adapt to evolving industry requirements without compromising the integrity of their production process.

D. Improved Safety and Reliability

- The use of 316L stainless steel push fittings in secondary battery manufacturing helps to mitigate the risk of leaks, failures, or other issues that could compromise the overall safety and performance of the battery products.

- The corrosion resistance and durability of these push fittings ensure the long-term reliability of the critical connections within the battery system, reducing the potential for catastrophic failures that could endanger both the manufacturing process and the end-user.

- By enhancing the safety and reliability of secondary batteries, 316L stainless steel push fittings play a crucial role in building consumer trust and fostering the widespread adoption of these energy storage solutions.

E. Enhanced Precision and Quality Control

- The consistent, high-quality construction of 316L stainless steel push fittings enables battery manufacturers to establish tighter tolerances and more precise control over the assembly process.

- This attention to detail and quality assurance helps to minimize the risk of defects or inconsistencies in the final battery products, ensuring a consistently superior level of performance and reliability.

- The enhanced precision afforded by 316L stainless steel push fittings also allows for more efficient production workflows, as battery manufacturers can streamline their quality control procedures and reduce the need for costly rework or replacement.

By harnessing the unrivaled benefits of 316L stainless steel push fittings, secondary battery manufacturers can elevate their operations to new heights of efficiency, safety, and cost-effectiveness, solidifying their position as leaders in this rapidly evolving industry.

V. How to Select and Implement 316L Stainless Steel Push Fittings for Secondary Battery Manufacturing?

Selecting the optimal 316L stainless steel push fittings for secondary battery manufacturing is a strategic endeavor, requiring a meticulous consideration of a multitude of factors to ensure seamless integration and long-term reliability. As battery manufacturers seek to harness the unparalleled benefits of these advanced connectors, a thoughtful and systematic approach to selection and implementation becomes paramount.

A. Comprehensive Evaluation of Technical Specifications

- Size and Dimensional Compatibility: Carefully assess the physical dimensions of the push fittings to ensure a precise fit within the battery’s internal architecture, maintaining optimal space utilization and component integration.

- Pressure Rating Suitability: Thoroughly evaluate the pressure-handling capabilities of the 316L stainless steel push fittings, aligning them with the specific demands of the battery’s cooling systems, fluid circuits, and other pressurized components.

- Material Compatibility: Ensure the push fittings’ compatibility with the diverse range of materials employed in the battery’s construction, including metals, plastics, and elastomers, to prevent potential incompatibility issues.

B. Sourcing from Reputable Manufacturers

- Quality Assurance and Certification: Prioritize 316L stainless steel push fittings sourced from manufacturers with a proven track record of quality, backed by rigorous testing and industry-recognized certifications.

- Technical Expertise and Support: Seek out suppliers who can provide comprehensive technical guidance and support, helping battery manufacturers navigate the selection process and ensure optimal implementation of the push fittings.

- Documented Installation and Maintenance Procedures: Collaborate with push fitting providers that offer detailed instructions and best practices for the proper installation, maintenance, and troubleshooting of these critical components.

C. Integrated Approach to Implementation

- Seamless Integration into Production Workflows: Carefully plan the integration of 316L stainless steel push fittings into the battery manufacturing process, ensuring a smooth transition that minimizes disruptions and optimizes production efficiency.

- Comprehensive Training and Knowledge Transfer: Equip the manufacturing team with the necessary skills and knowledge to handle the push fittings properly, fostering a culture of proactive maintenance and troubleshooting.

- Continuous Monitoring and Preventive Maintenance: Implement robust monitoring and inspection protocols to detect and address any potential issues with the push fittings before they compromise the integrity of the battery system.

By navigating the intricate landscape of 316L stainless steel push fittings with a methodical and strategic approach, secondary battery manufacturers can unlock the full potential of these advanced connectors, driving their operations towards new heights of safety, reliability, and cost-effectiveness.

VI. Types of 316L Stainless Steel Push Fittings

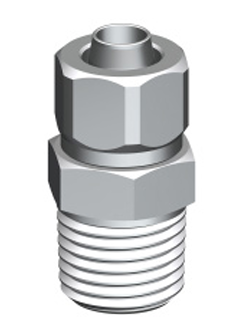

A. 316L Stainless Steel One-touch Fittings(316L Stainless Steel Push-in Fittings)

- Full 316L Stainelss Steel material for metal parts, FKM for seal parts

- Can be used with vacuum, steam

- Working Temperature: ﹣5-150°C

- Grease-free

- Cleanliness, Food Grade stainless steel fittings

- Leak-free

- Compact and lightweight

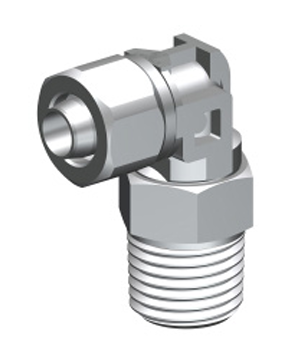

B. 316L Stainless Steel Insert Fittings(316L Stainless Steel Push-on Fittings)

- Full 316L Stainelss Steel material

- Can be used with vacuum, steam

- Working Temperature: ﹣65-260°C(No Freezing), (Swivel elbow and with sealant types:-5 -150℃)

- Grease-free

- Compact and lightweight

- Cleanliness, Food Grade stainless steel fittings

- Leak-free

VII. Conclusion

In the rapidly evolving world of secondary battery manufacturing, the use of high-quality components, such as 316L stainless steel push fittings, is crucial for ensuring the safety, reliability, and efficiency of the production process. By leveraging the exceptional corrosion resistance and durability of these push fittings, battery manufacturers can optimize their operations, reduce maintenance costs, and deliver superior products to the market. As the demand for secondary batteries continues to grow, the strategic deployment of 316L stainless steel push fittings will play a pivotal role in shaping the future of this dynamic industry.

For more information, please contact us !