When it comes to pneumatic systems, the air hose is not just a simple conduit for compressed air; it is a vital component that can significantly influence the overall performance, efficiency, and safety of your operations. Selecting the right air hose material is crucial, as it directly affects the hose’s durability, flexibility, and suitability for specific applications. With a variety of materials available—such as PVC, rubber, polyurethane (PU), nylon, and polyethylene (PE)—understanding the unique properties and applications of each is essential for making an informed decision. This article aims to provide you with comprehensive insights into air hose materials, their characteristics, and how to choose the best one for your needs.

Table of Contents

ToggleWhat Are the Common Materials Used for Air Hoses?

Air hoses are typically constructed from several materials, each offering distinct advantages and disadvantages. Here’s a detailed look at the most common materials used in air hoses:

1. PVC (Polyvinyl Chloride)

PVC is one of the most widely used materials for air hoses due to its affordability and lightweight nature. It is particularly suitable for low-pressure applications and is resistant to abrasion, making it a popular choice for general-purpose use. However, PVC hoses can become stiff and brittle in cold temperatures, which may lead to cracking or failure under stress. Therefore, while PVC is a cost-effective option, it may not be the best choice for environments with extreme temperature fluctuations.

2. Rubber

Rubber hoses are renowned for their durability and flexibility, making them ideal for heavy-duty applications. They can withstand high pressures and are resistant to wear and tear, which is crucial in industrial settings where hoses are subjected to constant movement and abrasion. Rubber hoses maintain their flexibility in both hot and cold conditions, ensuring reliable performance across a wide range of temperatures. If your application involves rigorous use, rubber hoses are often the best choice due to their robust nature.

3. Polyurethane (PU)

Polyurethane hoses have gained popularity in recent years due to their lightweight and flexible design. They are highly resistant to kinks and abrasions, making them suitable for applications where movement is frequent. PU hoses also exhibit excellent resistance to chemicals and oils, which is beneficial in automotive and manufacturing environments. Their ability to maintain flexibility in low temperatures further enhances their versatility. If you need a hose that combines flexibility with durability, PU is an excellent option.

4. Nylon

Nylon hoses are known for their strength and chemical resistance, making them suitable for high-pressure applications. They are lightweight and can handle a variety of environments, including those with exposure to chemicals and moisture. Nylon hoses are particularly effective in pneumatic systems that require robust performance under pressure. However, they may not be as flexible as rubber or PU hoses, so consider the specific requirements of your application when choosing nylon.

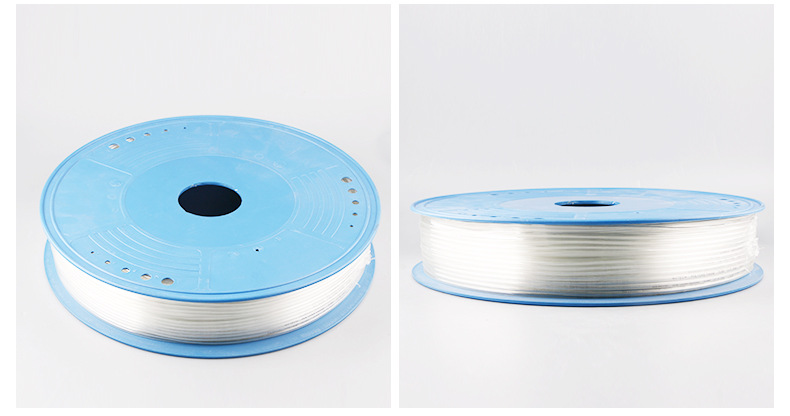

5. Polyethylene (PE)

Polyethylene hoses are durable and resistant to moisture and chemicals, making them ideal for outdoor applications. They are often used in agricultural and construction settings where exposure to the elements is a concern. PE hoses are lightweight and easy to handle, but they may not withstand high pressures as effectively as rubber or nylon hoses. If your application involves outdoor use or exposure to moisture, PE hoses can be a reliable choice.

How Does Temperature Affect Air Hose Material Selection?

Temperature is a critical factor in the performance of air hoses. Each material has a specific temperature range in which it operates optimally. For example, rubber hoses maintain their flexibility in both hot and cold conditions, making them suitable for a wide range of applications. In contrast, PVC hoses can become brittle in low temperatures, leading to potential failure.

When selecting an air hose, consider the temperature extremes your application may encounter. If your work environment involves high heat or extreme cold, choose a material that can withstand those conditions without compromising performance. For instance, rubber and PU hoses are often better suited for environments with significant temperature fluctuations.

What Are the Advantages and Disadvantages of PVC Air Hoses?

PVC air hoses are popular due to their cost-effectiveness and lightweight design. They are easy to handle and transport, making them suitable for various low-pressure applications. However, they do have limitations. In colder temperatures, PVC can lose its flexibility and may crack under stress. Additionally, PVC hoses may not be as durable as rubber or PU hoses in high-abrasion environments. If your application involves fluctuating temperatures or high wear, you might want to consider a more robust material.

Why Choose Rubber Air Hoses for Heavy-Duty Applications?

Rubber hoses are the go-to choice for heavy-duty applications due to their high durability and excellent flexibility. They can withstand high pressures and are resistant to abrasions, making them ideal for industrial settings where hoses are subjected to constant movement and wear. Rubber hoses maintain their flexibility in both hot and cold conditions, ensuring reliable performance across a wide range of temperatures. If you need a hose that can handle the rigors of demanding jobs, rubber is often the best option.

What Makes Polyurethane (PU) Hoses a Popular Choice?

Polyurethane hoses have gained popularity due to their lightweight and flexible nature. They are resistant to kinks, which can be a significant advantage in applications where movement is frequent. PU hoses also offer excellent abrasion resistance, making them suitable for various industries, including automotive and manufacturing. Their ability to maintain flexibility in low temperatures further enhances their versatility. If you’re looking for a hose that combines flexibility with durability, PU is an excellent choice.

When Should You Use Nylon or PE Hoses?

Nylon and PE hoses are ideal for specific applications due to their unique properties. Nylon hoses are strong and can handle high pressures, making them suitable for pneumatic systems that require robust performance. On the other hand, PE hoses are moisture-resistant and can withstand exposure to chemicals, making them perfect for outdoor applications. If your work involves harsh environments, consider these materials for their durability and resistance.

How Do Environmental Factors Influence Material Choice?

Environmental factors such as exposure to chemicals, UV light, and moisture can significantly influence your choice of air hose material. For instance, if your hose will be exposed to chemicals, nylon or PE may be the best options due to their chemical resistance. Similarly, if UV exposure is a concern, rubber or PU hoses may offer better longevity. Always assess the environment in which your hose will operate to ensure optimal performance.

What Are the Key Considerations for Air Hose Sizing and Fittings?

Proper sizing of air hoses is crucial for optimal airflow and pressure. A hose that is too small can restrict airflow, while one that is too large may lead to pressure drops. Additionally, ensure that the fittings you choose are compatible with the hose material. This compatibility is essential for maintaining a secure connection and preventing leaks.

When selecting fittings, consider the type of connection required for your application. Push-to-connect fittings, threaded fittings, and quick couplers each have their advantages and are suited for different scenarios. Ensure that the fittings match the hose diameter and material to avoid any issues during operation.

How Can You Ensure the Longevity of Your Air Hoses?

To maximize the lifespan of your air hoses, regular maintenance is key. Inspect hoses for signs of wear, such as cracks or abrasions, and replace them as needed. Proper storage is also important; avoid coiling hoses too tightly, as this can lead to kinks and damage. Additionally, keep hoses away from sharp edges and chemicals that could degrade the material. By taking these steps, you can ensure that your air hoses remain in good condition and perform effectively over time.

What Are the Best Practices for Selecting the Right Air Hose Material?

When selecting the right air hose material, consider the following factors:

- Application: Understand the specific requirements of your pneumatic system, including pressure, temperature, and flexibility needs.

- Environment: Assess the conditions in which the hose will operate, including exposure to chemicals, UV light, and moisture.

- Pressure and Temperature: Choose a material that can handle the pressure and temperature ranges of your application.

By taking these factors into account, you can make an informed decision that meets your needs.

Conclusion

Choosing the best air hose material is essential for the efficiency and safety of your pneumatic systems. By understanding the properties of different materials and considering the specific requirements of your application, you can select a hose that will perform reliably and last longer. If you have any questions or need personalized advice, feel free to reach out. Your pneumatic system deserves the best, and I’m here to help you make the right choice!