I’ve sized and specified stainless fittings for plants where a single undersized elbow stalled actuators across a production cell. Pneumatics look forgiving on paper, but in the field—with pressure drop stacking, inconsistent thread standards, and ferrule bite issues—small sizing mistakes become big reliability problems. I’m going to walk through how I choose tube OD, hose ID, and thread size, how I check tolerances and ferrules, how I avoid choking the system with low Cv, and the common pitfalls that drive leaks and sluggish response.

To size stainless steel fittings for pneumatic lines, I match the fitting to the tube or hose OD, the port thread standard (NPT, BSPP/G, BSPT, ISO), and the internal bore needed to maintain 6–9 m/s air velocity at the required SCFM with minimal pressure drop. I verify compression-ferrule tolerances and bite on the exact tubing spec, check the fitting’s Cv and bore against total system demand (including elbows/tees/quick-connects), and confirm pressure rating, media compatibility, and seal materials. Oversizing slightly on long runs or multi-drop circuits is often the cheapest way to prevent starvation and leaks.

In the sections below, I’ll show my step-by-step approach to calculating OD/ID/thread sizes, the specific checks I make on ferrules and tolerances, how I read Cv and bore data to avoid choke points, and the sizing mistakes I see most often in plants. I’ll add quick comparison tables and visual guides so you can apply this on your next design or retrofit.

Table of Contents

ToggleHow do I calculate the correct tube OD, hose ID, and thread size for my flow and pressure?

Start from flow, then velocity, then diameter

I size pneumatics from the required flow rate (SCFM) and acceptable air velocity. For general industrial air, I target 6–9 m/s in main headers and 4–6 m/s in instrument drops; faster air increases noise, erosion, and pressure loss. Given SCFM and line velocity, I compute the required cross-sectional area and then diameter. For compressible air, I still use velocity targets as a practical design heuristic, then validate with pressure drop calculations.

- Estimate line size: pick a diameter that keeps velocity at 6–9 m/s at your peak SCFM.

- Validate: use Darcy–Weisbach or proven pneumatic calculators to check kPa/psi drop across the run length, including fittings and valves.

Tube OD vs hose ID vs fitting conventions

- Push-to-connect pneumatic fittings are sized by tube OD (e.g., 6 mm, 8 mm, 10 mm; or 1/4″, 3/8″). That OD must match the tube exactly—no “close enough.”

- Compression fittings (stainless, instrumentation-style) are sized by tubing OD and require matching wall and material for reliable ferrule bite.

- Flexible hose is typically specified by ID because flow is governed by the bore; ensure the fitting barb or insert matches hose ID and the assembly maintains the intended bore.

- Threads are specified by standard and nominal size, which do not directly equal measured OD. Identify the port first, then select the matching thread.

Identify and match thread standards correctly

I never assume thread type—ports vary by OEM, geography, and product line.

- NPT (tapered): common in North America; seals with thread interference + PTFE tape/dope. Check TPI and taper.

- BSPP/G (parallel): common in EU/Asia; seals with an O-ring or bonded washer under a flat face.

- BSPT (tapered): similar concept to NPT but different pitch/form; don’t mix.

- ISO metric (parallel): often with O-ring face; identify pitch (e.g., M10x1).

I use thread gauges or verified charts to confirm pitch and major/minor diameters. If a component port is BSPP, I pick a stainless fitting with BSPP male and an appropriate seal; if it’s NPT, I pick NPT—adapters add restriction and leak risk, so I avoid them unless absolutely necessary.

Pressure rating and material compatibility

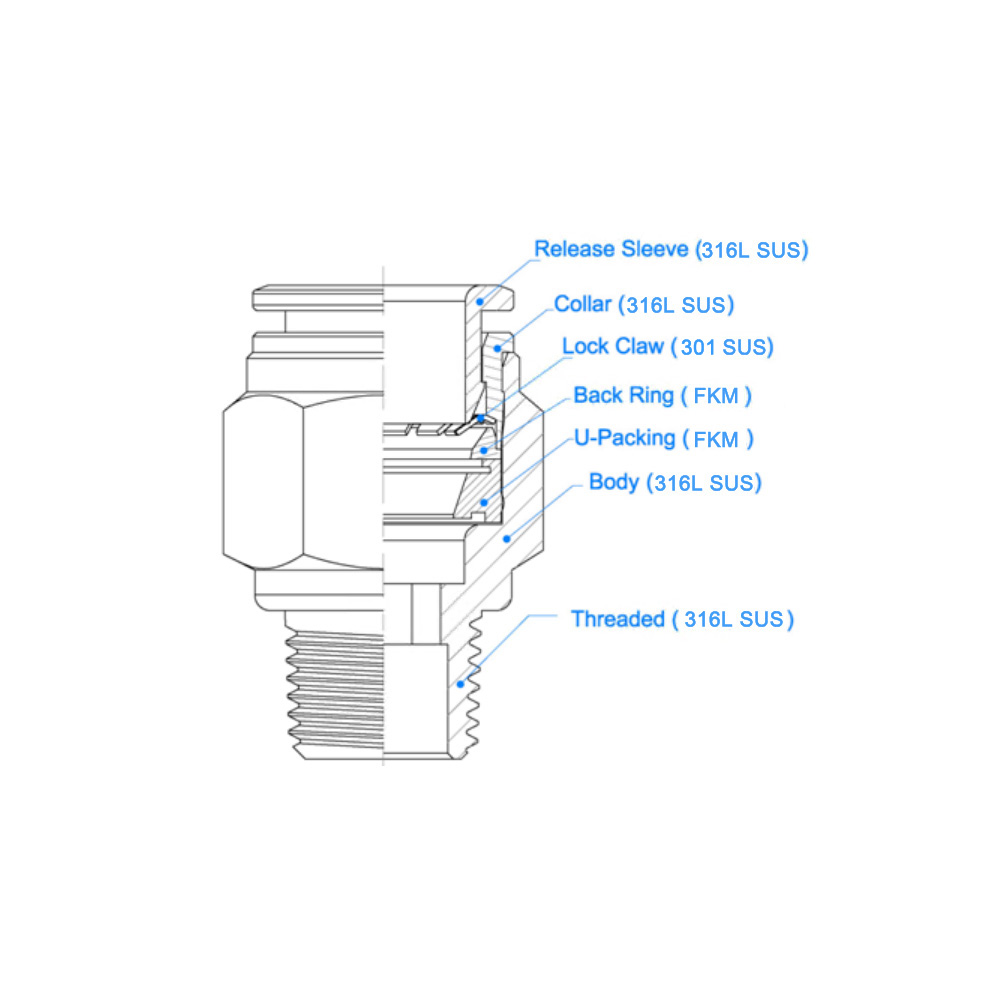

Once the line diameter is set, I confirm the fitting’s pressure rating at temperature. Stainless 316 instrumentation fittings commonly exceed typical plant air pressures (6–10 bar / 90–150 psi), but thin-wall tube or small-bore elbows can have lower limits. I match 316/316L stainless for corrosion resistance in moist, oil-laden compressed air and verify seal materials (FKM, NBR, PTFE) for temperature and media.

Quick selector table: size conventions and when to use

| Item | Sizing convention | Typical use | Notes |

|---|---|---|---|

| Push-to-connect fitting | Tube OD | General pneumatics | OD must match; bore varies by brand/series |

| Compression fitting (SS) | Tube OD + wall | Instrument air, clean environments | Ferrule bite depends on tube tolerance and hardness |

| Hose barb/insert | Hose ID | Flexible drops, tools | Check clamp type; avoid choking at barb |

| Threaded port | NPT, BSPP/G, BSPT, ISO | Component ports | Match standard; use seals appropriate to parallel/taper |

What should I check about tolerances and ferrule bite for compression fittings?

Compression fittings are unforgiving when tube tolerances drift. I check these before I greenlight a size:

Tubing OD tolerance and surface finish

- OD tolerance: use tubing that meets instrumentation-grade tolerances (e.g., per ASTM A269/A213). If OD runs undersize, ferrules won’t bite consistently; if oversize, assembly torque spikes and threads can gall.

- Surface finish: clean, smooth, free from scratches and ovality. Out-of-round tube causes partial ferrule bite and leaks under thermal cycling.

Wall thickness and hardness

- Wall thickness: too thin and the ferrule can collapse the tube; too thick and seating may be incomplete at recommended torque. Stainless ferrules typically specify compatible wall ranges—stay inside them.

- Hardness: 316/316L tubing hardness affects ferrule penetration; mixing hard ferrules with very soft tube (or vice versa) changes bite profile. I stick to matched systems (fitting brand + tubing spec) for predictable results.

Ferrule design and installation torque

- Single vs double ferrule: double-ferrule designs give better vibration resistance and sealing in small-bore pneumatics; single-ferrule can work but is less tolerant of minor misalignment.

- Torque control: use manufacturer torque or turn-count method (e.g., 1-1/4 turns past finger-tight for initial make-up) and consistent lubrication practices. Over-torque deforms ferrules and can crack nuts; under-torque leaves micro-leaks.

Proof tests and re-makes

- Pressure test at operating pressure plus a margin; if the system cycles, add leak-down checks after thermal and vibration exposure.

- Re-make guidance: some systems allow a limited number of re-makes; beyond that, ferrule geometry is compromised. I mark fittings after first make-up to track rework.

How do I ensure the fitting bore and Cv won’t choke my system?

Even with a correct OD, the internal bore of the fitting can be the bottleneck. I focus on the flow path, not just the envelope size.

Read Cv and internal bore, not just connection size

- Cv is the flow coefficient: higher Cv means lower pressure drop at a given flow. Two 1/4″ fittings can have vastly different Cv due to internal geometry.

- I compare Cv across fittings, valves, quick-connects, and FRLs in the circuit. The “worst” component typically sets the system response.

Manage cumulative restrictions

Every elbow, tee, reducer, or QC adds equivalent length and minor loss. I sum these:

- Convert each fitting to an equivalent length factor, or use manufacturer loss coefficients (K).

- Validate total pressure drop end-to-end at peak demand; aim to keep actuator supply drops below ~10% of header pressure for crisp response.

Keep velocity in range; oversize prudently on long runs

- Long lines with multiple drops: I upsize one nominal size to keep velocity near 6 m/s, especially where multiple cylinders or blow-offs share a branch.

- Instrument lines: small-bore tube is fine, but ensure the fittings and regulators have matching or higher Cv so the instrument doesn’t lag.

Cv and bore comparison (illustrative)

| Connection size | Typical ID range | Typical Cv range | Use guidance |

|---|---|---|---|

| 1/4″ tube fitting | ~3.5–4.5 mm | 0.2–0.6 | Single small cylinder, short run |

| 3/8″ tube fitting | ~5–6 mm | 0.5–1.2 | Medium cylinder, moderate run |

| 1/2″ tube fitting | ~6.5–8 mm | 1.0–2.5 | Larger cylinder, long run or multi-drop |

Numbers vary by brand/series; I always pull the actual datasheet values for the chosen fitting.

What sizing mistakes commonly cause pressure drop or leak risk in my plant?

I see these repeatedly, and they cost energy and uptime.

Mixing thread standards and sealing methods

- NPT into BSPP with brute force and tape: partial thread engagement, poor face seal, chronic weep.

- Parallel thread without gasket: relies on thread to seal—leaks under vibration. Use bonded washer or O-ring as designed.

Undersized branches feeding multiple devices

- One 1/4″ branch feeding a valve bank and two cylinders: velocity spikes, regulator droop, slow actuation. Upsize the branch or split loads.

“Looks right” OD/ID but choked bore

- Slim-line fittings or compact elbows with small through-holes: Cv too low. Pick the high-flow series or move up a size.

Ignoring cumulative fittings and quick-connect losses

- Quick-connects can be surprisingly restrictive; stacking two QCs, a reducer, and an elbow near the tool causes big drop. Choose high-flow QCs and minimize transitions.

Poor tube tolerance and ferrule mismatch

- Commodity tube with wide OD tolerance: inconsistent ferrule bite, micro-leaks after cycles. Use instrumentation-grade tube matched to the fitting system.

Over-torque and galling in stainless

- Dry assembly of stainless threads: galling and seized nuts. I use appropriate lubricant or anti-seize approved for pneumatics and follow torque guidance.

Long runs without upsizing

- 20–30 m runs at small bore: acceptable at low flow but starves on peak. Upsize one nominal size; it’s cheap insurance.

Neglecting compressor diversity and peaks

- Lines sized for average flow: during tool blow-offs or simultaneous cylinder strokes, pressure sags. I size branches to handle peaks or add local accumulators.

Conclusion

When I size stainless steel pneumatic fittings, I start from peak flow and velocity targets, then translate that into tube OD or hose ID that keeps pressure drop in check. I match the exact thread standard and seal type to the component ports, and I verify Cv and internal bore so the fitting doesn’t become the hidden bottleneck. For compression fittings, I insist on tight tubing tolerances, correct wall/grade, and disciplined torque so ferrules bite cleanly and stay leak-tight. Finally, I audit the whole circuit—elbows, tees, quick-connects, regulators—because cumulative minor losses matter more than any single part number. If you keep velocity sensible, pick high-flow bores, and respect thread/seal standards, your plant will see faster actuators, fewer leaks, and lower energy costs.