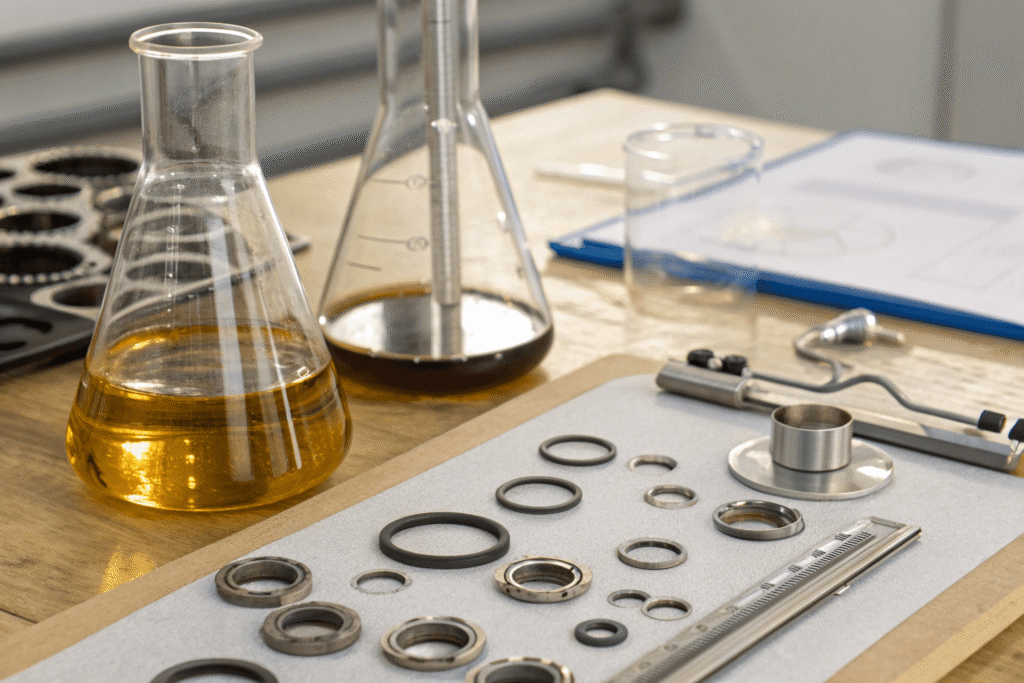

Selecting the right elastomer or polymer for seals in pneumatic components and automation systems is one of the most consequential decisions you’ll make. The wrong choice leads to swelling, hardening, leaks, and premature downtime; the right choice delivers stable compression set, predictable friction, and long service life across your operating envelope.

Match seal materials to the dominant media and worst-case temperature first, then validate with compatibility charts and application-specific tests. In short: NBR for petroleum oils, EPDM for water/steam and ozone, FKM for fuels and high-temperature chemicals, and PTFE for near‑universal chemical resistance and extreme temperatures—supported by test data (Shore A, compression set, and cycling).

Below, we’ll walk through compatibility references for oils, ozone, and chemicals, how to balance low-temperature flexibility with resistance, what data to request from suppliers, and the testing protocols that de‑risk your selection for pneumatic lines and manifolds.

Table of Contents

ToggleWhat compatibility charts should I use for oils, ozone, and chemicals in my lines?

Choosing seals is ultimately a media-management problem. We start by identifying dominant fluids, additives, cleaning agents, and ambient exposures (ozone/UV), then screen candidate materials against trusted compatibility data.

Use recognized chemical compatibility charts and standards to shortlist materials, then confirm with supplier-specific datasheets and targeted lab tests. Prioritize the most aggressive or dominant media when there’s mixed exposure.

Recommended references and how to use them

- Manufacturer and distributor charts: Use curated charts from established seal suppliers to quickly scan ratings (excellent/good/poor) for NBR, FKM, EPDM, and PTFE across oils, fuels, solvents, acids, bases, and ozone. Cross-check two sources to avoid single-chart bias.

- ASTM D471 immersion test data: Look for or commission D471 results for your exact media. Metrics include volume change, hardness change, tensile/elongation changes after 24–168 hours at set temperatures.

- Ozone/UV resistance data: EPDM typically rates “excellent”; NBR “poor”; FKM varies by grade; PTFE is non-elastomeric and not affected in the same way. Validate outdoor or cabinet-vented installations that pull ozone-laden air.

- Mixed-media approach: If your line encounters oil mist plus periodic solvent rinses, choose based on the more aggressive solvent, not the oil. Where trade-offs are tight, consider dual-material strategies (e.g., main seal in FKM, wipers in NBR).

Pro Tip: Document all non-process exposures—assembly lubricants, thread sealants, cleaners, inhibitors—then check each against your candidate elastomer. These “incidental” chemicals often cause early seal degradation.

Quick compatibility pointers for common exposures

- Petroleum oils and fuels: NBR (baseline, economical), FKM (high-temp/additives). Avoid EPDM.

- Ozone/UV outdoors: EPDM excels; NBR poor; FKM generally good; PTFE unaffected.

- Polar solvents/hot water/steam: EPDM preferred; FKM grades may degrade in steam; PTFE for harsh chemistries.

- Broad-spectrum solvents/acids/bases: PTFE favored; consider spring-energized profiles for leakage control.

| Material | Typical compatible media | Pros | Considerations |

|---|---|---|---|

| NBR | Mineral oils, hydraulic fluids | Economical, good compression set | Poor ozone/UV; limited high temp |

| FKM | Fuels, hydrocarbons, many solvents | High temp and chemical resistance | Not for hot steam/strong amines/ketones (grade-dependent) |

| EPDM | Hot water, steam, brake fluids, polar solvents | Excellent ozone/weathering, low-temp flexibility | Not suitable for mineral oils/fuels |

| PTFE | Acids, bases, oxidizers, solvents | Near-universal chemical resistance, wide temp range | No elasticity, creep; needs energizers/support |

How do I balance low-temperature flexibility with chemical resistance?

In pneumatics, low-temperature start-up and pressure cycling can punish stiff seals. At the same time, aggressive media demands higher resistance. The material choice is a trade-off between glass transition behavior, compression set, and solvent resistance.

For cold starts, EPDM or low-temperature NBR grades maintain flexibility; for aggressive chemicals and heat, FKM or PTFE step in. Where you need both, consider specialty low‑temperature FKM grades or hybrid designs (elastomeric primary seal, PTFE backup).

Practical decision path

- Below −30°C to −50°C: EPDM is dependable for water/steam systems; low‑temp NBR for oil systems. Standard FKM may stiffen below −20°C—use specialty low-temp FKM grades if needed.

- −20°C to +100°C mixed exposure: Choose based on media. Oils → NBR; fuels/solvents → FKM; water/steam → EPDM. Validate compression set at your specific temperature.

- >150°C or solvent-rich: FKM often sufficient; if strong oxidizers/harsh acids/bases are present, move to PTFE with spring-energized lip designs to address creep and sealing force.

- Dynamic motion and cycling: Elastomers (NBR/EPDM/FKM) offer better resilience and lower compression set. PTFE requires mechanical energizers or preloaded designs to maintain contact under cycling.

Caution: A seal that passes chemical compatibility may still leak at cold start due to high stiffness. Specify low‑temperature compression set and glass transition characteristics where winter operation or refrigerated environments are expected.

Can I request compound hardness (Shore A) and compression set data for my seals?

Absolutely—and you should. Hardness, compression set, and tensile/elongation are core to predicting sealing force, leakage risk, and service life under pneumatic cycling.

Request full compound datasheets: Shore A hardness, compression set (at relevant temp/time), tensile strength, elongation, specific gravity, and any regulatory compliance (FDA, RoHS). Ask for typical and tolerance ranges, not just nominal values.

What to request from suppliers

- Shore A hardness: Specify target (e.g., 70 ±5 Shore A for O-rings) aligned with groove design, pressure, and installation ease.

- Compression set: Request at your operating and worst-case temperatures (e.g., 22h at 100°C and 24h at −20°C for elastomers; protocol per ASTM D395). Lower values indicate better resilience.

- Tensile/elongation: Confirms robustness during installation and pressure cycling.

- Volume/swell data: For your specific media (ASTM D471). Avoid >10% volume change as a general rule of thumb.

- Temperature capability: Continuous and intermittent ratings for the exact grade (NBR, FKM, EPDM). PTFE grades should list crystalline transition considerations and creep behavior.

- Regulatory and traceability: ISO 9001 process control, material batch certificates, and CE/RoHS/FDA documentation where applicable.

Pro Tip: Ask for first‑article samples with batch-specific test reports and perform a fit-and-function trial in your actual hardware. Verify hardness on arrival (durometer) and dimensional tolerances (ISO 3601 for O-rings) before mass production.

What testing should verify seal performance under cycling and pressure?

Lab validation bridges the gap between charts and real-world reliability. Pneumatic seals see repeated pressure pulses, micro‑motion, and varying humidity/temperature—so test what you’ll actually run.

Combine bench chemistry (immersion and property change) with application-level endurance (pressure cycling, leakage rate, and burst/extrusion tests). Use accelerated conditions that mimic worst-case service.

Test plan essentials

- Chemical immersion (ASTM D471): Measure volume change, hardness shift, tensile/elongation after exposure to your actual oils/solvents/cleaners at operating temperatures.

- Compression set (ASTM D395): At multiple temperatures to capture cold-start and hot soak behavior.

- Pressure cycling and leakage: Cycle at expected min/max pressures and frequencies; record leakage vs. time. Include temperature ramps and humidity/ozone if relevant.

- Extrusion and wear: For high differential pressures or poor clearances, run extrusion-resistance tests with representative hardware gaps; evaluate surface finish (Ra) effects on wear.

- Steam and water aging (for EPDM): Condition seals in hot water/steam and re-measure properties.

- Dimensional stability and creep (PTFE): Long-hold tests under preload to quantify creep; use spring-energized designs if creep is unacceptable.

- Threaded fitting validation: If seals sit in BSPT/NPT assemblies, verify thread standards and seal compression under torque ranges to avoid spiral leaks.

Example acceptance criteria (customize for your system)

- Volume change ≤10% after D471 immersion in target fluid at operating temp.

- Compression set ≤25% at service temp; ≤35% at worst‑case temp spike.

- Leakage below defined ppm or sccm threshold across full pressure cycle profile.

- No visual cracking, blistering, or excessive swelling after accelerated exposure.

Material selection playbook for pneumatics and automation

We often blend materials to optimize performance and cost while maintaining safety margins. Here’s a concise framework aligned to typical pneumatic systems.

Start with the dominant media and temperature, select the baseline material, then tune hardness and geometry. Where chemistry is extreme or mixed, use PTFE with energizers or upgrade elastomer grade.

Typical scenarios

- Mineral oil mist lubrication, ambient temps: NBR 70 Shore A O-rings; validate compression set and leakage at cycle frequency.

- Outdoor air lines with moisture and ozone: EPDM seals for manifolds and FRLs; ensure stainless hardware and ozone-resistant hoses.

- Fuel vapor handling or solvent purge: FKM seals; check grade-specific limits for ketones/amines; consider low-temp FKM for cold climates.

- CIP/SIP in food and beverage: FDA‑compliant EPDM for water/steam lines; PTFE for aggressive cleaners; verify documentation and traceability.

- Chemical dosing or corrosive gases: PTFE seals with spring‑energized lips; confirm hardware support to mitigate creep and extrusion.

Caution: Some low-cost fittings use recycled brass or unspecified additives; residual oils and cleaners can attack seals unexpectedly. Specify post‑process cleaning and passivation, then review residual chemistry against your selected elastomer.

Cost and performance considerations

Balancing budget with reliability is practical in B2B sourcing. NBR is usually lowest cost and fastest to procure; EPDM is modestly higher; FKM is premium; PTFE costs vary with geometry and energizers.

Cost climbs with temperature and chemical performance. Reduce total cost by validating the cheapest acceptable material via testing instead of over‑specifying by default.

| Condition | Recommended material | Notes |

|---|---|---|

| Hydraulic/mineral oil (<100°C) | NBR | Upgrade to FKM for >100°C or aggressive additives |

| Water/steam (<150°C) | EPDM | Validate steam cycles; avoid oils |

| Fuels/aromatics | FKM | Check low-temp FKM grades for cold starts |

| Harsh chemicals/acids/bases | PTFE | Use spring-energized for seal force; design supports |

| Outdoor/ozone | EPDM | Excellent weathering; verify UV exposure |

| Mixed media, moderate temp | FKM | Prioritize the most aggressive chemical |

Supplier documentation and quality control

For buyers sourcing pneumatic components from China (Ningbo, Wenzhou, Dongguan, Yuhuan are key hubs), insist on transparent material traceability and inspection.

Request batch CoAs, hardness and compression set reports, and pre‑shipment inspection. Align threads (BSPT vs. NPT), seal grooves, and materials early to avoid rework.

What to specify in RFQs

- Material grade and Shore A hardness with tolerance

- Compression set targets and test temperature

- Media list for D471 immersion tests

- Dimensional standard (e.g., ISO 3601 for O-rings)

- Regulatory requirements (CE, RoHS; FDA where applicable)

- Packaging and lot traceability; desiccant for moisture‑sensitive elastomers

Pro Tip: Always request a first-article inspection before mass production to confirm thread standards, groove dimensions, and sealing materials. Include photos, durometer readings, and leak tests in the FA report.

Conclusion

Selecting NBR, FKM, EPDM, or PTFE for pneumatic seals comes down to an honest assessment of your media and temperature extremes, then validating with compatibility charts and targeted testing. NBR fits petroleum oils and budgets; EPDM thrives in water/steam and ozone; FKM handles fuels and high heat; PTFE covers aggressive chemicals and extreme temperatures—with energizers to offset creep.

Looking for reliable pneumatic component suppliers in China or help interpreting seal data? Contact us for a customized sourcing consultation and a test plan tailored to your media, temperature, and cycling profile.