If you work with compressed air day in and day out, you already know leaks are stealthy profit killers. They inflate energy bills, reduce available pressure at the point of use, and mask deeper reliability problems in fittings, manifolds, and valves. In production, I’ve seen a single loose push-to-connect fitting drop a line’s pressure by 10–15 psi and trigger nuisance faults on pick-and-place systems.

To detect air leaks quickly and accurately, start with low-cost visual and tactile screening (soapy solution, listening, tissue), confirm system-wide leakage using pressure decay or load/offload analysis, then use ultrasonic detectors to pinpoint micro-leaks in noisy areas. Map and tag each leak, quantify the energy loss, and prioritize repairs by leak rate, accessibility, and impact on uptime.

Below, I’ll walk through the tools, procedures, and prioritization methods we use in the field. I’ll also show how to calculate energy losses and which joints typically leak first under vibration—so your maintenance schedule targets the highest ROI fixes.

Table of Contents

ToggleWhat tools—soapy solution, ultrasonic sensors, and pressure tests—work best for me?

Selecting the right tool depends on your goals: fast triage, comprehensive detection, or quantified testing. I always recommend stacking methods—from simple to advanced—to cover both obvious and micro-leaks.

Tiered detection approach

- Stage 1: Quick screening for accessible fittings

- Soapy water solution or commercial leak fluid

- Listening for hissing; tissue or lightweight tape to feel airflow

- Stage 2: System-level confirmation

- Pressure decay test (isolate and watch gauge drop)

- Compressor load/offload time-based leakage estimate

- Stage 3: Precision pinpointing

- Ultrasonic leak detector (handheld pistol-grip)

- Acoustic imaging camera for larger plants or noisy lines

How to perform each method

Soapy solution and commercial leak sprays (fast visual confirmation)

- Mix dish soap and water in a spray bottle, or use a dedicated, non-corrosive leak detection fluid rated for compressed air systems.

- Pressurize the circuit, spray fittings and joints, and watch for bubbles. Rapid bubbling indicates a substantial leak; slow bubble growth points to micro-leaks.

- Commercial sprays often outperform household soap on micro-leaks due to optimized surfactants and film stability.

Ultrasonic leak detectors (precision under noise)

- These detect ultrasonic frequencies (typically 35–65 kHz) generated by turbulent escaping air.

- Sweep at 5–10 feet, volume high; once you hear the “jet” signature, move closer and dial sensitivity down to pinpoint the source.

- Advantages: Works in noisy environments, identifies small leaks at distance, quantifies relative severity.

Pressure decay test (yes/no system leak confirmation)

- Pressurize to normal operating pressure.

- Isolate the section with shutoff valves.

- Monitor gauge drop over a fixed time. A rapid drop confirms significant leakage; a slow, steady drop signals minor leakage or temperature-induced changes.

Load/offload leakage estimation (no shutdown needed)

- Measure compressor load time (charging) and offload time (idling).

- Estimate leak rate with: Leak Rate (%) ≈ [Load Time × 100] / (Load Time + Offload Time).

- A result greater than ~10% suggests meaningful leakage. This is a quick KPI for plant managers.

Handheld electronic gas leak detectors

- Useful if your compressed air includes detectable additives or mixed gases (e.g., nitrogen/CO2 blends in certain processes).

- Confirm sensor compatibility; air alone may not trigger these unless calibrated for turbulence signatures.

Comparison: speed, cost, reliability

| Method | Speed | Cost | Sensitivity | Best Use |

|---|---|---|---|---|

| Soapy solution | Fast | Very low | Medium to high | Visual pinpointing of accessible fittings |

| Commercial leak fluid | Fast | Low | High | Micro-leaks, professional repeatability |

| Ultrasonic detector | Fast to moderate | Medium | Very high | Noisy areas, long runs, elevated piping |

| Pressure decay | Moderate | Very low | System-level | Confirming if leakage exists in a zone |

| Load/offload | Fast | None | System-level | Ongoing KPI without shutdown |

| Tissue/listen | Very fast | None | Low to medium | Triage, prioritizing where to spray |

| Acoustic imaging | Very fast | High | Very high | Large facilities with limited downtime |

How do I map leak points and calculate energy losses in my plant?

Finding leaks is only half the job. The value comes from tracking, quantifying, and closing the loop with verification. When we started mapping leaks, our plants saw 20–30% reductions in compressor runtime within a quarter.

Step-by-step leak mapping workflow

Prepare a zone-based plan

- Isolate sections with shutoff valves where possible.

- Assign routes: headers, drops, manifolds, machine boundaries, then tool connections.

Tag each leak

- Use durable tags with ID numbers.

- Record location (line, drop, machine, port), fitting type, and estimated size/severity.

Capture photos

- Snap the bubbling location or ultrasonic screen capture.

- Store in your CMMS or a shared drive for traceability.

Quantify severity

- Use bubble vigor, ultrasonic decibel scale, or orifice estimation.

- Log pressure at time of detection; pressure affects leak rate.

Schedule repair windows

- Group fixes by accessibility, required parts (O-rings, ferrules, PTFE tape, sealant), and lockout needs.

Re-verify after repair

- Repeat the exact detection method used. No tag is closed without a clean retest.

Estimating leak flow and energy cost

For planning, I use a practical rule-of-thumb alongside more precise calculations.

- Rule-of-thumb at ~100 psig:

- 1 mm hole ≈ ~3–4 scfm

- 2 mm hole ≈ ~12–15 scfm

- Energy estimate:

- kW to compress air is system-dependent, but a typical plant might spend ~0.18–0.25 kW per scfm at 100 psig (including compressor efficiency).

- Cost per year per scfm ≈ scfm × kW/scfm × hours/year × $/kWh.

Example:

- Leak measured/estimated at 10 scfm.

- kW/scfm = 0.20; plant runs 6,000 hours/year; electricity $0.10/kWh.

- Annual cost ≈ 10 × 0.20 × 6,000 × 0.10 = $1,200 per leak.

If you have an ultrasonic detector with relative readings, rank leaks by “signal strength” and calibrate a few with an actual flow measurement (temporary flow meter on a branch line or calibrated leak orifice). That correlation gives you plant-specific cost curves without metering every leak.

Simple table: leak mapping fields to capture

| Field | Example | Why it matters |

|---|---|---|

| Tag ID | Z3-DROP12-F2 | Traceability and scheduling |

| Location | Zone 3, drop 12, fixture F2 | Speeds return visit |

| Fitting type | 1/4 NPT to push-to-connect, brass | Predicts typical failure mode |

| Detection method | Ultrasonic, 55 kHz, level 6 | Consistent retesting |

| Pressure | 100 psig | Normalizes flow estimates |

| Severity | Medium (approx. 6–8 scfm) | Prioritization |

| Root cause | Loose threads, worn O-ring | Preventive actions |

| Repair | Re-torque, replace sealant and O-ring | Documentation |

| Re-verify | Passed (no bubbles, low ultrasonic) | Close the loop |

Which joints and manifolds tend to leak first under vibration in my machines?

Vibration accelerates fatigue, loosening, and seal wear. In packaging lines, CNC auxiliaries, and robotic cells, I consistently find early leaks at joints where motion meets threaded connections.

High-risk leak points under vibration

- Push-to-connect fittings at moving axes

- Tubing creep and ovalization reduce grip; collet wear allows micro-movement.

- Threaded NPT joints on manifolds

- Tapered threads can back off or crack sealant under cyclic loads.

- Valve islands and sub-bases

- O-ring face seals compress/relax; manifold gaskets harden and shrink.

- Cylinder ports and rod seals

- Rod side sees side-loads, misalignment, and vibration—rod wipers and seals wear fast.

- Quick couplers and whip hoses

- Repeated connect/disconnect; dynamic loads loosen ferrules and clamps.

Material and design considerations

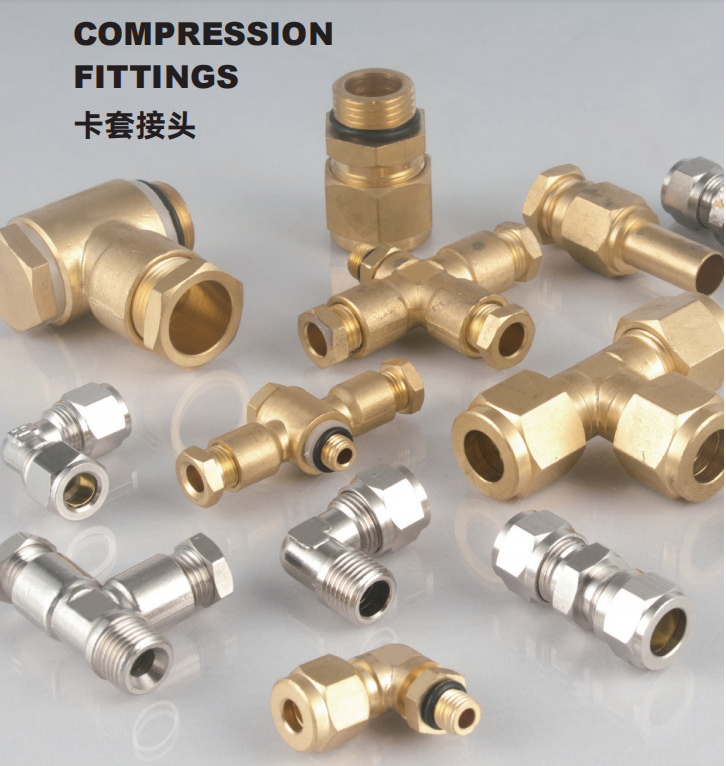

- Fitting body materials

- Brass: easy to install, but softer—may deform under over-torque.

- Stainless steel: higher strength; preferred in high-vibration or corrosive environments.

- Polymer push-in bodies: lightweight; ensure rated for vibration and pressure cycles.

- Sealing media

- PTFE tape: prone to shredding if over-tightened or reworked; use proper wrap direction and thread engagement.

- Paste sealants (anaerobic): consistent sealing; better in vibration if manufacturer-approved for air systems.

- O-rings: NBR for general air, FKM for heat/chemicals; verify hardness (durometer) and compatibility.

Preventive measures I recommend

- Use captive thread sealants and torque to spec

- A torque wrench prevents both loose and over-tightened fittings.

- Add strain relief and clamps

- Secure tubing near vibration sources; avoid cantilevered loads on fittings.

- Upgrade to anti-vibration fittings or stainless bodies

- Particularly on manifolds near motors and gearboxes.

- Inspect cylinder alignment and cushion settings

- Misalignment and harsh stops transmit shock into ports and seals.

- Implement lock-wire or thread locker where permissible

- For non-service joints that must not back off; follow manufacturer and safety guidance.

How should I prioritize repairs to maximize savings and reliability in my schedule?

Prioritization turns a long leak list into measurable savings. The trick is combining leak rate, accessibility, and impact on downstream equipment.

A practical prioritization matrix

| Priority Tier | Criteria | Typical Actions |

|---|---|---|

| Tier 1 (Immediate) | Large leaks (>10 scfm), safety concerns, critical pressure drops affecting production | Lockout, re-torque, reseal or replace fittings; verify pressure recovery |

| Tier 2 (High) | Medium leaks (3–10 scfm), leaks near control valves/sensors causing faults | Replace O-rings, refresh PTFE or apply approved sealant, tighten to spec; add strain relief |

| Tier 3 (Scheduled) | Small leaks (<3 scfm), hard-to-access elevated piping, non-critical | Batch repairs during planned downtime; consider component upgrades |

| Tier 4 (Preventive) | Known vibration zones, aging manifolds, recurring joints | Proactive replacement program; material upgrades; add clamps and supports |

Scheduling best practices

- Group by parts and tools

- Stock O-ring kits, sealants, PTFE tape, ferrules, and spare fittings. Nothing kills momentum like missing a $2 part.

- Zone-based closures

- Complete one zone, re-verify, then move on. It keeps wins tangible and measurable.

- Track compressor KPIs

- After each repair batch, monitor load/offload times, header pressure stability, and energy use. The savings should show up quickly.

- Standardize torque values

- Build a torque spec library by fitting size/material. Over-torque damage is as common as under-torque leaks.

Common causes vs. fixes

| Cause | Why it leaks | Fix |

|---|---|---|

| Loose threads | Vibration or improper installation | Torque to spec; apply compatible sealant |

| Over-tightened NPT | Cracked threads or damaged sealant | Replace fitting; reassemble to spec |

| Worn O-rings | Age, heat, chemical exposure | Replace with correct elastomer and size |

| Tubing creep in push-in | Movement and temperature cycles | Cut fresh square end; ensure full insertion; add clamps |

| Poor sealant selection | Incompatible or degraded | Use air-rated anaerobic sealant or proper PTFE tape method |

| Misalignment at cylinders | Side-load on ports/seals | Correct mounts; adjust cushions; replace seals |

Field-tested how-to: from detection to verification

Here’s a condensed procedure we run in plants for fast results:

- Confirm leaks exist: Isolate a header and perform a pressure decay test. If drop is notable, proceed.

- Triage: Walk the zone, listen for hissing, and use tissue to flag obvious suspects.

- Visual pinpoint: Spray soapy solution or commercial leak fluid on flagged fittings and all nearby joints. Tag each leak.

- Precision sweep: Use an ultrasonic detector to find micro-leaks on manifolds, valve islands, and elevated lines.

- Repair batch: Re-torque, re-seal, replace O-rings/PTFE/threads as needed. Follow manufacturer torque specs and material compatibility.

- Re-verify: Spray or scan the repaired points. Remove tags only after clean results.

- Record savings: Update your CMMS with severity and repair time; monitor compressor load/offload or kWh to validate ROI.

Conclusion

Compressed air leaks aren’t just a maintenance nuisance—they’re a direct drain on energy and reliability. The fastest path to savings is a layered detection strategy: confirm with pressure tests, locate leaks with soapy solution and ultrasonic tools, then map, tag, and quantify each point. In my experience, the biggest wins come from consistent inspection, correct torque and sealing practices, and upgrading high-vibration joints near manifolds and cylinders. The key is simple: standardize the workflow, verify every repair, and watch your compressor runtime—and costs—fall.