Air leaks are a quiet profit drain. I’ve walked into plants where compressor rooms are working overtime, yet operators are fighting pressure drop at the far end of the line. Nine times out of ten, it’s not an undersized compressor—it’s a network of small leaks across push-to-connect fittings, threaded joints, valve manifolds, quick couplers, and fatigued tube bends. The good news: with a disciplined leak hunting method and the right repair materials, you can reclaim pressure, reduce compressor runtime, and cut energy costs quickly.

The most efficient approach is to combine a structured leak audit with practical detection tools—pressure decay tests to flag sections, soap-and-water for visible bubbling, and ultrasonic detection to pinpoint small, inaudible leaks. Log each leak, prioritize by estimated flow and cost, then repair with proper tube cuts, correct thread/sealant practices, and material-compatible O-rings or tubing. Validate with a defined leak rate (e.g., SCFM per circuit), document baseline values, and schedule routine audits to keep savings on track.

Below I outline the field-proven method we use in production environments—what to check, how to repair, and how to verify fixes before you restart the line.

Table of Contents

ToggleWhat step-by-step leak hunting method should I use on my lines?

In my experience, a good leak hunt is part triage, part science. Start wide to find suspect zones, then narrow down to exact points.

Prepare and segment the system

- Map circuits and isolate sections (zones, manifolds, branches). Lockout/tagout where required.

- Bring each isolated section to normal operating pressure.

- Identify common leak points first: push-to-connects, threaded joints, valve manifolds, quick couplers, and tube bends that vibrate.

Run a quick pressure decay test

- Pressurize the isolated section.

- Close the supply valve to that section.

- Monitor the pressure gauge for decay over 2–10 minutes.

- If pressure drops beyond your allowable threshold, you’ve confirmed leakage in that segment.

Why it works: Pressure decay tests quickly tell you whether searching is worth your time in a given zone before you start scanning every joint.

Use tiered detection tools

- Soap-and-water solution: Spray suspected fittings and joints. Bubbles indicate leaks. This is fast, cheap, and great for medium leaks.

- Ultrasonic leak detector: Scan around fittings, manifolds, and along tubing. It hears high-frequency turbulence you can’t. Adjust sensitivity to avoid false positives near exhaust ports.

- For complex installs or noisy plants, acoustic imaging can visualize leak hotspots, especially near manifolds and couplers.

Confirm exact leak points

- Mark each leak with a durable tag and a unique ID.

- Note component type (e.g., 1/4″ PU tube into push-in fitting, NPT thread into manifold).

- Record operating pressure at time of detection.

Decide immediate vs. scheduled repair

- If a leak threatens production pressure or safety, fix immediately.

- Otherwise, queue into a prioritized repair plan (see next section on logging and prioritization).

Quick reference: common causes vs. detection

| Common leak point | Typical cause | Best detection method |

|---|---|---|

| Push-to-connect fittings | Tube not fully seated past O-ring; burrs; worn O-ring | Soap bubbles + ultrasonic at fitting |

| Threaded joints (NPT/BSPP/BSPT) | Incorrect thread type; poor sealant; over/under-torque | Ultrasonic + visual; confirm thread spec |

| Valve manifolds | Gasket/O-ring wear; loose ports | Ultrasonic; acoustic imaging for dense areas |

| Quick couplers | Worn seals; misfit plug; contamination | Soap bubbles; ultrasonic directly at sleeve |

| Tube bends under vibration | Micro-cracks; abrasion; kinking | Visual + ultrasonic along tube length |

How do I log and prioritize leak points for energy savings in my plant?

You can’t fix what you don’t track. A disciplined log delivers ROI by focusing the team on the leaks that meaningfully reduce compressor load and improve pressure at end-use points.

What to log for each leak

- ID, location (line/zone/manifold), asset tag if applicable

- Component type and size (tube OD, thread type), operating pressure

- Detection method (soap, ultrasonic, pressure decay)

- Estimated leak size/flow (if available from device or rule-of-thumb)

- Severity (A, B, C) based on impact on pressure drop, compressor runtime, and safety

- Planned repair method and materials

- Date detected, date repaired, technician, validation reading post-repair

Prioritization logic

- Target “A” severity leaks first: those near the compressor header, large fittings, quick couplers feeding multiple tools, or any leak affecting end-of-line pressure stability.

- “B” severity: medium leaks around machine cells, especially where operators complain about tool torque or cycle time drift.

- “C” severity: small leaks to be bundled into scheduled maintenance windows to minimize downtime.

Example prioritization matrix

| Priority | Criteria | Typical examples | Action |

|---|---|---|---|

| A (High) | Audible or high ultrasonic signal; affects end-use pressure; near main headers | Worn quick coupler at tool cluster, manifold O-ring failure | Repair immediately; verify with flow/pressure test |

| B (Medium) | Moderate leak; localized impact | Push-to-connect at cylinder port; thread seep at regulator | Schedule within 1–2 weeks; bundle parts |

| C (Low) | Small leak; minimal impact | Minor seep at gauge port; micro-bubbles on enclosure line | Repair during PM; monitor trend |

Estimating energy impact for ROI

- Use plant compressor data (load/offload times) and leak estimation to rank savings.

- A single 1/4″ leak at 100 psi can cost thousands annually in electricity; dozens of small leaks add up.

- Prioritizing by energy impact reduces compressor runtime, extends equipment life, and often postpones the need for capacity upgrades.

Which sealants and replacement parts are best for fast, reliable repairs?

Speed matters—but reliability matters more. The best repairs follow proper assembly disciplines and use materials compatible with the environment and pressure.

Push-to-connect fittings and tubing

- Technique: Cut tube square with a sharp tube cutter; remove burrs; ensure a clean outer surface. Push fully past the O-ring until you feel the shoulder. Pull back lightly to seat.

- O-rings: Replace worn O-rings. Choose material based on environment:

- NBR (Buna-N): general purpose

- Viton (FKM): heat/chemical resistance

- EPDM: steam or certain chemicals (avoid with oils)

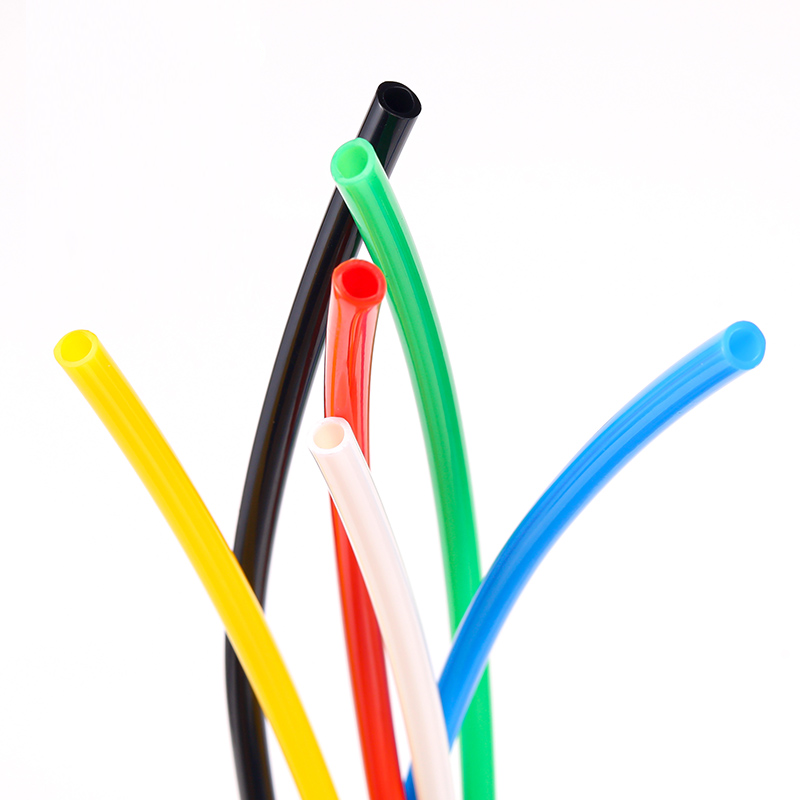

- Tubing materials:

- Polyurethane (PU): flexible, good for robotics and vibration-prone runs

- Nylon (PA): higher pressure, better dimensional stability

- PTFE or PFA: chemical resistance, high temperature

- Tip: If tubing shows abrasion or flattening at bends, add support (bend restrictors) or reroute with a proper bend radius.

Threaded connections: NPT vs. BSPP/BSPT

- Identify thread type before repair; mixing standards causes persistent microleaks.

- Sealants:

- PTFE tape: 3–4 wraps clockwise on male threads; avoid over-application that can shred and contaminate valves.

- Anaerobic thread sealant with PTFE: superior sealing, vibration resistant; allow proper cure time per manufacturer.

- Torque: Follow fitting specs; over-torquing can crack housings or distort threads, inviting leaks.

Quick couplers and manifolds

- Replace worn coupler seals; ensure plug/coupler series compatibility.

- For manifolds, inspect port gaskets/O-rings and mounting flatness; replace with OEM kits.

- Keep contaminants out: particulate can score sealing surfaces; use filtration and clean assembly practices.

Replacement parts checklist

- Correct thread standard and size (NPT, BSPP, BSPT)

- Tube OD and material compatible with pressure, temperature, and chemicals

- O-ring material matched to environment (NBR/Viton/EPDM)

- Sealant type suitable for temperature and pressure; consider cure time

- Avoid reusing compression sleeves/ferrules—once deformed, they won’t reseal reliably

Materials and applications quick guide

| Component | Best material choice | Application notes |

|---|---|---|

| Tubing for flexible lines | Polyurethane | Resists kinking; absorbs vibration; moderate pressure |

| Tubing for high pressure | Nylon | Better burst strength; stiffer; good for fixed runs |

| O-rings in heat/chemicals | Viton (FKM) | Higher temp; chemical compatibility |

| General O-rings | NBR (Buna-N) | Cost-effective; broad compatibility |

| Chemical lines | PTFE/PFA tubing | Excellent chemical resistance; use compatible fittings |

How do I validate repairs with pressure tests before restarting production?

Validation separates guesswork from reliability. I always insist on a measured leak limit per circuit and a documented baseline.

Define your allowable leak rate

- Set a per-circuit limit (e.g., SCFM at operating pressure) based on process sensitivity and compressor capacity.

- Align to internal standards and reference ISO testing concepts where applicable.

Verification tests

1) Pressure decay test

- Isolate and pressurize repaired section.

- Close supply; monitor for defined time.

- Accept if pressure drop stays within allowable limit.

2) Flow or mass leak test

- Use a calibrated flow meter or mass flow sensor inline.

- Measure steady-state leakage at operating pressure.

- Compare to your defined SCFM limit and previous baseline.

3) Functional checks

- Cycle affected actuators and valves at normal duty.

- Verify end-of-line pressure stability and that the compressor doesn’t increase load cycles.

Documentation and trend monitoring

- Record pre- and post-repair readings (pressure decay curve, SCFM).

- Update leak log with repair date, parts used, and validation results.

- Track plant-wide baseline monthly; a rising baseline indicates new leaks or component aging.

Validation criteria table

| Test | Pass criteria | Notes |

|---|---|---|

| Pressure decay | ≤ defined psi drop over test interval | Interval typically 2–10 min per circuit |

| Flow leak rate | ≤ defined SCFM limit | Use calibrated sensors; note temp/pressure |

| Functional run | Stable pressure at end-use, normal compressor cycling | Observe at least one full production cycle |

Conclusion

In our experience, leak management is one of the fastest ways to improve pneumatic performance and cut energy costs without capital expense. A repeatable method—segment, pressure decay test, pinpoint with soap and ultrasonic, then repair with correct materials and assembly practices—delivers reliable results. The key is consistent inspection, proper component selection, and disciplined validation against a defined leak rate. Do that, and you’ll see fewer nuisance faults, steadier pressure at tools, and a quieter compressor room that isn’t fighting to keep up.