I’ve watched perfectly good machines go down because a $4 tube split mid-shift. When that happens, teams blame “bad tubing” or “wrong brand,” but in my experience the root causes are rarely that simple. Pneumatic tubing lives at the intersection of pressure cycles, bending, chemicals, heat, UV, and the realities of installation in tight spaces. If any one factor is poorly controlled—especially over time—microcracks, embrittlement, or stress concentrations can quietly accumulate until the tube fails “under normal use.”

Most pneumatic tubing bursts or cracks because cumulative stress exceeds the material’s real-world strength: cyclic pressure, surges, temperature derating, UV/ozone, chemicals, and bending beyond the minimum radius all compound. Even within “spec,” transient spikes or improper fittings can drive localized stress beyond the wall’s capacity. The fix is holistic: verify derated pressure/temperature, ensure chemical/UV compatibility, honor bend radius and routing, and add QA tests to catch aging or extrusion defects early.

In the sections below, I’ll break down how pressure/temperature interplay, environmental exposure, and routing realities create failure modes; how to diagnose them; and what QA checks to request from suppliers. I’ll also share material and fitting selection practices that have consistently reduced leak rates and extended life in OEM and retrofit projects.

Table of Contents

ToggleAm I exceeding working pressure or temperature ratings without noticing?

Pressure ratings vs. reality

In my designs, I never treat a catalog “working pressure” as unconditional. That rating assumes a standard temperature (often 20–23°C), steady-state loading, and clean, dry air. In service, pressure pulsations from fast-acting valves and actuators can easily spike 1.5–3× above regulator setpoints. Water hammer effects occur when trapped condensate slugs meet quick exhausts. These transient peaks drive local hoop stress beyond the wall’s yield, initiating microcracks that later appear as “random bursts.”

- Pressure safety factors: Many pneumatic tubes are designed with a nominal burst ratio of 3:1 to 4:1 versus working pressure at 23°C. At 50–60°C, the effective burst margin can drop sharply due to temperature derating.

- Cv and actuation timing: High-Cv valves feeding small volumes create rapid dP/dt. I’ve mitigated spikes by adding snubbers, flow controls, or larger volume near actuators to damp the transient.

Temperature derating and ambient sources

I scrutinize nearby heat sources—motors, ovens, manifolds, welding cells—and the effect of enclosure temperatures. Polyurethane (PU) and nylon ratings fall with heat; PU ester grades soften and creep earlier than ether grades. Cold environments are just as sneaky: subfreezing air makes many polymers brittle, lowering impact strength and making bend points crack under normal pressure.

- Always apply the manufacturer’s derating curve: At 60°C, a tube rated 10 bar may effectively be safe at 6–7 bar.

- Combine derating with surges: If your normal operating is 6 bar with 2× transient spikes, that tube may experience brief conditions equivalent to 12 bar at 50°C—well into failure territory.

Practical checks I run

- Log pressure with high-speed sensors for a full cycle; don’t rely solely on regulator gauges.

- Verify compressor cycles, dump valve behavior, and FRL setpoints under load.

- If heat is present, move to higher-temp polymers (PTFE, FEP, PFA) or nylon 12, add shielding, and route away from hot surfaces.

Is UV, ozone, or chemical exposure embrittling my tubing?

UV and ozone

Even “indoor” plants can see significant UV through skylights; outdoor or near-UV processes are worse. I’ve seen black carbon-filled tubing hold up much longer than translucent variants under UV. Ozone attacks double bonds in elastomers and some polyether chains, producing surface crazing that grows under static strain.

- Countermeasures: Use UV-stabilized black tubing, add covers, and avoid static tension. For ozone-prone environments (e.g., corona treaters, high-voltage equipment), select ozone-resistant materials (PTFE, FEP, certain ether-based PU, EPDM for hoses).

Chemical incompatibility and hydrolysis

Chemical incompatibility is a silent killer. Cleaning agents (isopropanol, ketones, esters), oils, and certain process gases plasticize or depolymerize the tube. Ester-based PU is especially vulnerable to hydrolysis in humid or wet systems; it goes cloudy, stiff, then cracks. Nylon absorbs moisture (hygroscopic), shifting dimensions and mechanical properties.

- Match media and cleaning chemicals to materials: Ether-based PU resists hydrolysis better than ester-based. PTFE/FEP handle solvents and aggressive chemicals but need proper fittings to avoid cold-flow leaks.

- Consider permeation: CO2, fuel vapors, and some solvents permeate certain polymers, swelling and weakening walls over time.

What I specify

- Request a chemical compatibility chart from the supplier for conveyed media and plant cleaners.

- If washdown or humidity is high, select ether-based PU or nylon 12, and ensure drains/dryers are effective.

- For solvent-laden environments, PTFE or PFA tubing with compression fittings (stainless ferrules) is my default.

How do bending radius and improper routing contribute to failures?

Minimum bend radius and kinking

When installers force a tight turn, the inner wall goes into compression and the outer wall into tension, creating a stress gradient that grows cracks at the outer arc. Kinks flatten the lumen, increasing local velocity and erosive wear while concentrating stress; over time, small surface fissures evolve into longitudinal splits.

- Respect minimum bend radius: I design with 20–30% margin beyond the catalog spec for dynamic applications (robots, carriages).

- Add strain reliefs: Spring guards, grommets, or right-angle fittings at terminations prevent sharp turns and kink initiation.

Routing near edges, clamping, and rub points

Sharp sheet metal, cable trays, and moving linkages abrade tubing. Particulate-laden air can erode the inner wall; externally, vibration against edges creates notch effects that amplify stress. Over-clamped bundles act like rigid beams, driving high strain at clamp exits.

- Avoid hard 90° panel exits; use bulkhead connectors with radiused bushings.

- Space clamps to allow gentle arcs; use soft inserts in metal clips.

- Keep tubing out of pinch points and away from reciprocating guards.

Fittings and termination stress

I see many failures originate within 10–20 mm of a fitting. Overtightened compression nuts, oversized barbs, or wrong ferrule material cut or cold-flow the tube. Misaligned push-to-connect fittings force a side load, creating a permanent bend and stress riser.

- Select fittings to match tube material: Brass barbs for PU; stainless compression for PTFE; anodized aluminum bodies for weight-sensitive systems; nickel-plated brass for corrosion resistance.

- Don’t over-torque; follow manufacturer torque spec. Use support sleeves for soft tubing to prevent collapse under the ferrule.

What QA checks should I request to catch aging or material defects early?

Incoming inspection and material verification

I ask suppliers for lot-level traceability and run quick checks on arrival:

- Dimensional: OD/ID and wall thickness uniformity (± tolerance). Uneven extrusion introduces weak zones.

- Hardness and tensile samples: Durometer consistency and tensile strength spot checks reveal improper compounding.

- Visual: Surface pitting, voids, gels, die lines; ends cut cleanly without feathering (indicates brittleness).

Aging and performance tests

Aging reveals formulations that look fine at day one but fail at month six.

- Accelerated aging: 70°C oven exposure for 7–14 days, then bend/pressure test; UV chamber exposure (per ASTM G154) for surface cracking propensity.

- Pressure proof and burst: Hydrostatic or pneumatic proof at 1.5× working pressure; burst testing and leak-down curves. Record failure mode (longitudinal split vs. pinhole) to diagnose process vs. material issues.

- Flex fatigue: Mandrel cycling at specified radius to simulate robotics; count cycles to crack initiation.

Chemical and environmental compatibility

- Soak tests: Immerse segments in process chemicals/cleaners for 24–72 hours; measure mass change, hardness shift, visual crazing.

- Ozone exposure: ASTM D1149-style evaluation for crack growth under strain.

Supplier documentation I request

- Resin type (e.g., PU ether vs. ester), additives (UV stabilizers), and lot certificates.

- Temperature–pressure derating curve, minimum bend radius by size, and recommended fittings/ferrules.

- ISO/ASTM compliance references (e.g., ISO 2398, ISO 6807 for hoses; manufacturer’s internal standards for industrial tubing).

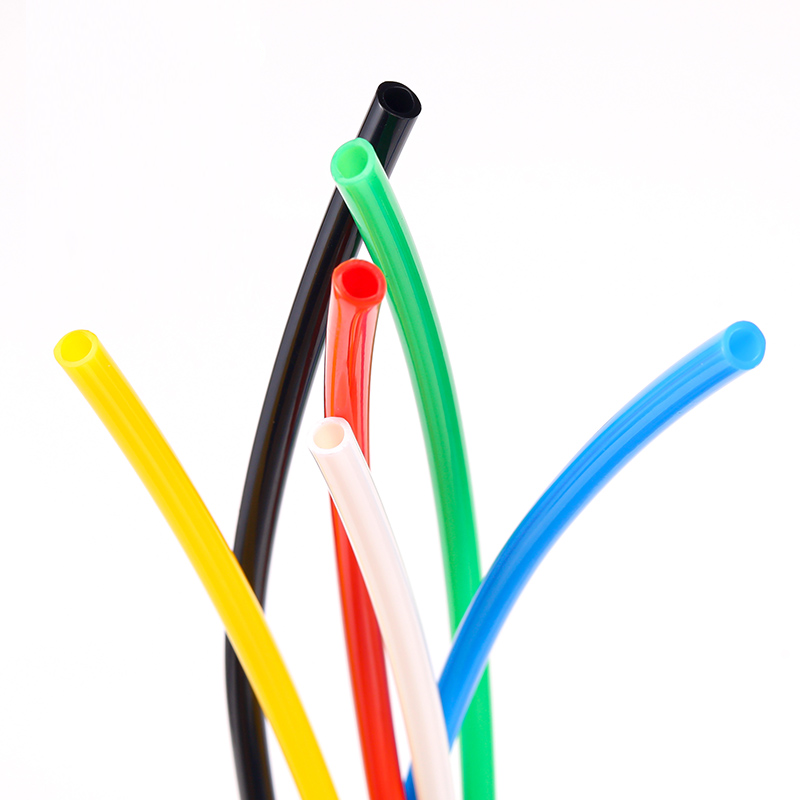

Material comparison quick reference

| Material | Strengths | Limitations | Typical Use Cases |

|---|---|---|---|

| PU (ether-based) | Flexible, kink-resistant, better hydrolysis resistance | Moderate chemical resistance, derates with heat | General pneumatics, robotics, manifolds |

| PU (ester-based) | Cost-effective, flexible | Hydrolysis-prone in humid/wet environments | Dry indoor air, non-washdown |

| Nylon 12 | Higher pressure, good abrasion resistance | Hygroscopic; stiffness can crack if over-bent cold | Long runs, panel plumbing, industrial lines |

| PTFE/FEP/PFA | Excellent chemical/temperature resistance, low friction | Needs proper compression fittings; can cold-flow | Solvents, aggressive gases, high-temp zones |

| PVC | Economical | Poor high-temp/solvent resistance; plasticizer issues | Low-pressure, non-critical lines |

Pressure and temperature guidelines

| Parameter | Good Practice | Risk Indicator |

|---|---|---|

| Working pressure | Keep ≤70–80% of derated limit | Frequent spikes >1.5× setpoint |

| Temperature | Apply OEM derating curve; shield hot spots | Ambient >50°C or subfreezing cycles |

| Bend radius | Design ≥1.2–1.3× minimum for dynamic | Kinks, white stress marks at bends |

| Fittings | Match tube-to-ferrule; torque to spec | Cracks within 20 mm of fitting |

Troubleshooting checklist I use on-site

- Log actual pressure transients at 1–5 ms resolution; add snubbers/flow controls if spikes are high.

- Verify FRL: Drain filters, set regulators, check lubricator carryover; remove oil for tube materials that swell.

- Inspect routing: Replace tight bends with elbows; add strain relief; move away from heat, UV, and edges.

- Swap to compatible materials: Ether-based PU for humid; PTFE/FEP for solvents; black UV-stabilized tubing near windows.

- Re-terminate fittings: Correct barb size, add support sleeves, align push-to-connect bodies, re-torque per spec.

- Implement QA: Proof-pressure testing on incoming lots; accelerated aging and UV checks for critical lines.

Conclusion

When pneumatic tubing fails “under normal use,” it’s almost always the sum of small, overlooked stresses: transient pressure peaks, temperature derating, UV/ozone exposure, solvent cleaners, tight bends, and fitting-induced stress. I prevent these by combining better materials with disciplined routing, verified pressure/temperature derating, and targeted QA tests that catch extrusion or compounding issues before installation. The payoff is real—lower leak rates, fewer nuisance shutdowns, and longer intervals between tubing replacement.