Table of Contents

Toggle1. Introduction

In the ever-evolving landscape of the pulp and paper industry, where operational efficiency and product quality reign supreme, the selection of mission-critical components has become a strategic imperative. As processing equipment and systems face relentless exposure to harsh chemical environments, corrosive conditions, and extreme temperature fluctuations, the choice of materials used in these critical components can mean the difference between sustained productivity and costly downtime.

Introducing 316L Stainless Steel – the premier solution for pneumatic fittings that are purpose-built to withstand the rigors of modern pulp and paper operations. Renowned for its unparalleled corrosion resistance, exceptional durability, and hygienic design, this advanced alloy is poised to elevate your processing capabilities, safeguard product integrity, and drive lasting success in your industry.

Whether you’re seeking to optimize existing systems or design new, state-of-the-art facilities, 316L Stainless Steel pneumatic fittings from Ideal-bell offer the reliable performance and resilience your operations demand. Unlock the full potential of your pulp and paper workflows and position your organization for long-term growth and profitability.

2. The Advantages of 316L Stainless Steel Pneumatic Fittings

As the pulp and paper industry continues to evolve, so too must the components that power its critical operations. 316L Stainless Steel stands out as the premier material choice for pneumatic fittings, offering a dynamic combination of benefits that can elevate your processing capabilities and ensure uninterrupted, high-quality production.

A. Corrosion Resistance

The pulp and paper industry is known for its highly acidic and moisture-rich environments, which can wreak havoc on lesser-quality materials. 316L Stainless Steel, however, is renowned for its exceptional corrosion resistance, ensuring your pneumatic fittings maintain their structural integrity and performance over the long haul.

B. Durability

From high pressure spikes to extreme temperature fluctuations, the demands placed on pneumatic fittings in pulp and paper mills are immense. 316L Stainless Steel is engineered to withstand these harsh conditions, providing unparalleled strength and reliability that translates to reduced maintenance and extended service life.

C. Hygienic Design

Maintaining product purity is a top priority in the pulp and paper industry. 316L Stainless Steel’s smooth surfaces and resistance to bacterial growth make it the ideal choice for pneumatic fittings, minimizing the risk of contamination and ensuring the integrity of your final products.

D. Chemical Compatibility

The diverse range of industrial fluids and gases used in pulp and paper operations requires pneumatic fittings that can adapt to a variety of chemical environments. 316L Stainless Steel’s exceptional chemical compatibility ensures compatibility with your specific system requirements.

3. Key Features of Our 316L Stainless Steel Pneumatic Fittings

A. Comprehensive Product Range

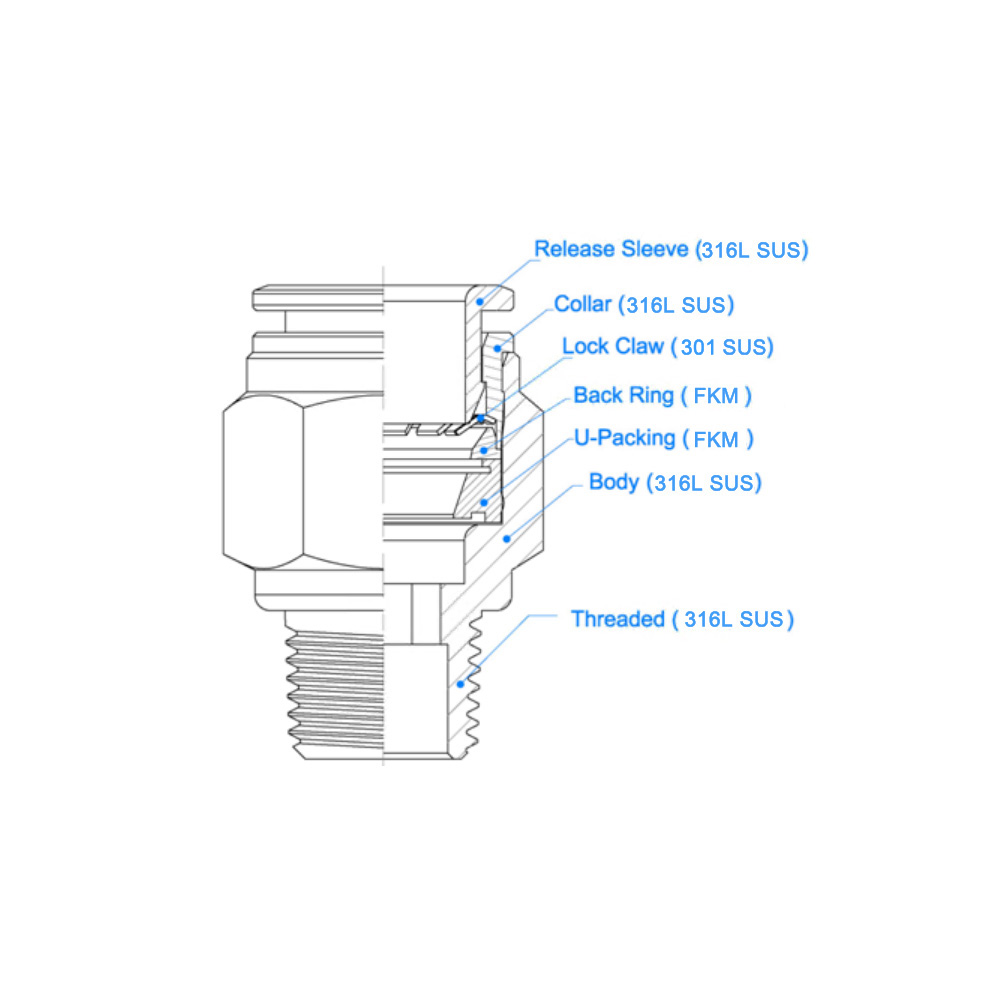

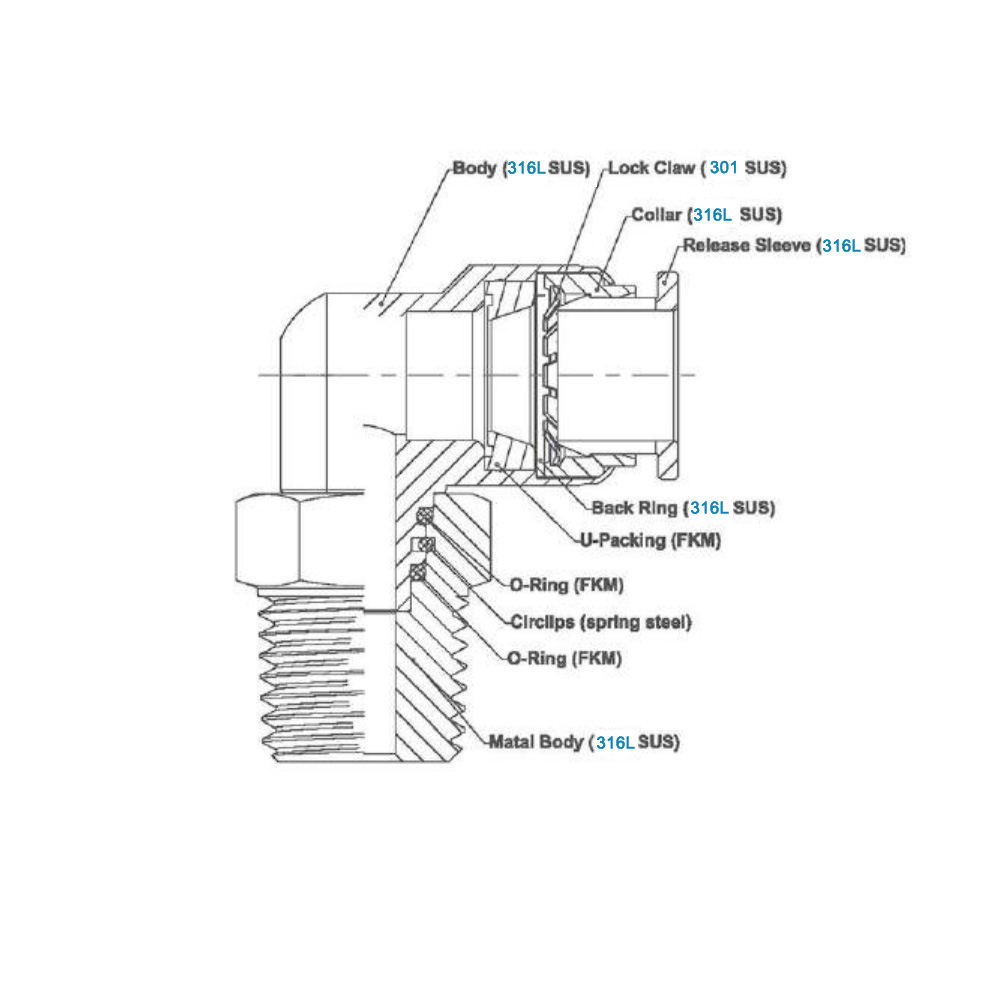

Our 316L Stainless Steel pneumatic fittings, here refer to 316L Stainless Steel Push to Connect Fittings(push-in fittings) include a wide array of straight, elbows, tees, unions, and more, ensuring we have the perfect solution for your unique system configuration.

The normal specification and pressure rating for 316 stainless steel fittings

- Applicable Fluid Type: Air, Water,Vacuum

- Working Pressure Range:-14 ~290 PSI, -0.99~ 20 Bar

- Working Temperature Range: 5 ℉ ~428 ℉, -15℃ ~220℃

- Vacuum Rating: to 750mmHg

- Recommanded Tubings: PA11, PA12, PA6, PE, PU,PTFE,FE

316L Stainless Steel Push-to-Connect Fittings Sizes:

- Tube size: Metric – 4mm ~12mm; Inch size – 5/32″~1/2″

- Thread size: M5, M6, U10, 1/8″-1/4″

- Thread type: BSPT(R or PT), BSPP(G), NPT

B. Superior Craftsmanship

Every 316L Stainless Steel pneumatic fitting we offer is precision-engineered to the highest standards, ensuring exceptional performance and reliability in even the most demanding pulp and paper environments.

C. Easy Installation

Streamlined designs and intuitive installation features make our 316L Stainless Steel pneumatic fittings a breeze to integrate into your existing systems, minimizing downtime and simplifying maintenance.

4. Benefits of Upgrading to 316L Stainless Steel Pneumatic Fittings

Enhanced System Reliability: By choosing 316L Stainless Steel pneumatic fittings, you can rest assured that your critical processing equipment and systems will operate with unparalleled dependability, minimizing costly downtime and maintenance expenses.

Improved Productivity: Uninterrupted performance and consistent operation translate directly to higher output and greater efficiency in your pulp and paper operations, giving you a competitive edge in the market.

Increased Safety: The rugged construction and corrosion resistance of 316L Stainless Steel pneumatic fittings provide an added layer of protection for your workers, safeguarding them from potential leaks, failures, or other hazardous events.

Long-Term Cost Savings: While the initial investment in 316L Stainless Steel pneumatic fittings may be slightly higher, the long-term cost savings in reduced replacement and repair expenses make it a prudent and strategic choice for the pulp and paper industry.

5. Conclusion

In the demanding world of pulp and paper production, reliability is the hallmark of success. By investing in 316L Stainless Steel pneumatic fittings from ideal-bell, you can elevate your operations, boost productivity, and gain a competitive edge in the market. Unlock the full potential of your pulp and paper systems – contact us today to learn more about our premium-quality solutions.

316L ss fittings & 316L ss flow controls For High Durable in Corrosive Applicaitons: