Introduction

Pneumatic systems rely on a network of tubes, fittings, and valves to transport compressed air or gas between components. One type of fitting that has gained popularity in recent years is the push-to-connect fitting. Push-to-connect fittings are a type of quick-connect fitting that allows for easy and secure connections between pneumatic components.

Push-to-connect fittings work by using a collet mechanism to grip onto the tubing and create a secure seal. The collet is made up of several metal fingers that grip onto the tubing when it is inserted into the fitting. This creates a secure and leak-proof connection that can withstand high-pressure and high-temperature environments.

The advantages of using push-to-connect fittings in pneumatic systems are numerous. These fittings are easy to install, create a secure connection between pneumatic components, are versatile, durable, and cost-effective. We’ll explore these advantages in more detail and explain why push-to-connect fittings are a smart choice for businesses that use pneumatic systems.

The Advantages of Using Push-to-Connect Fittings

1. Easy Installation

Push-to-connect fittings are designed for easy installation, which is one of their biggest advantages. Unlike traditional fittings that require special tools and training, push-to-connect fittings can be installed quickly and easily without any special equipment.

To install a push-to-connect fitting, simply push the tubing into the fitting until it clicks into place. The collet mechanism will grip onto the tubing and create a secure seal. This process can be completed in a matter of seconds, without the need for any special tools or training.

This ease of installation can save businesses time and money. With push-to-connect fittings, businesses can install these fittings themselves without the need for a professional installer. This can help reduce installation costs and downtime, as businesses can quickly and easily make changes to their pneumatic systems as needed.

In addition, push-to-connect fittings can be easily removed and reused if necessary. This can help businesses save money on replacement fittings and reduce waste.

Overall, the easy installation process of push-to-connect fittings can save businesses time and money, while also providing a secure and reliable connection between pneumatic components.

2. Secure Connection

Push-to-connect fittings create a secure and reliable connection between pneumatic components. The collet mechanism used in push-to-connect fittings ensures a tight grip onto the tubing, creating a leak-proof seal. This can help prevent leaks and improve system performance.

The secure connection created by push-to-connect fittings is especially important in high-pressure and high-temperature environments. These environments can put a strain on pneumatic systems, causing leaks and other issues. Push-to-connect fittings can help prevent these issues by creating a secure connection that can withstand the demands of these environments.

In addition, push-to-connect fittings can help improve system performance by ensuring that air flows smoothly through the system without any interruptions. The secure connection created by push-to-connect fittings can help prevent air leaks, which can cause pressure drops and reduce the efficiency of the system.

Overall, the secure connection created by push-to-connect fittings is an important advantage for businesses that use pneumatic systems. It can help prevent leaks, improve system performance, and ensure that the system operates reliably and efficiently.

3. Versatility

Push-to-connect fittings can be used in a wide range of pneumatic applications, making them a versatile and flexible choice for businesses. They can be used with a variety of tubing materials, including polyurethane, nylon, and polyethylene. This versatility allows businesses to adapt to changing pneumatic needs and use push-to-connect fittings in a wide range of applications.

Push-to-connect fittings can also be used in both low-pressure and high-pressure systems. This makes them a flexible choice for businesses that need to adapt to different pressure requirements. In addition, push-to-connect fittings can be used with a variety of pneumatic components, including valves, regulators, and actuators.

The versatility of push-to-connect fittings can help businesses save time and money by reducing the need for different types of fittings for different applications. By using push-to-connect fittings, businesses can streamline their pneumatic systems and reduce the complexity of their inventory.

Overall, the versatility of push-to-connect fittings makes them a flexible and adaptable choice for businesses that use pneumatic systems. They can be used in a wide range of applications and can help businesses save time and money by reducing the need for different types of fittings.

4. Durability

Push-to-connect fittings are designed to withstand high-pressure and high-temperature environments. They are made from durable materials such as brass, stainless steel, and nickel-plated brass. This makes them a durable and long-lasting choice for businesses that require reliable connections in harsh environments.

Push-to-connect fittings are also designed to resist corrosion and wear, which can help extend their lifespan. This durability can help businesses reduce maintenance costs and avoid costly downtime due to failed fittings.

In addition, push-to-connect fittings are designed to be resistant to vibration and shock. This can help prevent fittings from becoming loose or disconnected due to vibrations or sudden impacts.

Overall, the durability of push-to-connect fittings makes them a reliable and long-lasting choice for businesses that use pneumatic systems. They can withstand harsh environments, resist corrosion and wear, and remain secure even in high-vibration environments.

5. Cost-Effective

While push-to-connect fittings may be slightly more expensive than traditional fittings, they can be a cost-effective choice in the long run. Their ease of installation, reliability, and durability can help businesses save money on installation and maintenance costs over time.

Push-to-connect fittings are a cost-effective choice for businesses due to their ease of installation, reliability, and durability. These fittings are designed to be installed quickly and easily, without the need for special tools or training. This means that businesses can save money on installation costs, as they do not need to hire specialized personnel to install the fittings.

In addition, push-to-connect fittings are highly reliable, with a proven track record of performance in a variety of applications. They are designed to provide a secure, leak-free connection, which helps to prevent costly downtime and repairs. This reliability can also help businesses save money in the long run, as they can avoid the costs associated with frequent repairs and replacements.

Finally, push-to-connect fittings are highly durable, with a long service life that can help businesses save money over time. These fittings are typically made from high-quality materials, such as brass or stainless steel, that are resistant to corrosion and wear. This means that they can withstand the rigors of daily use, even in harsh environments, and continue to perform reliably for years to come.

Overall, the cost-effectiveness of push-to-connect fittings makes them an ideal choice for businesses looking to save money on installation and maintenance costs. By choosing these fittings, businesses can enjoy the benefits of reliable, durable performance, without breaking the bank.

Furthermore, push-to-connect fittings can also help businesses save money by reducing the need for additional components. These fittings are designed to connect directly to tubing or piping, without the need for additional adapters or fittings. This can help to simplify the installation process and reduce the number of components required, which can help to save money on both material and labor costs.

Additionally, push-to-connect fittings are often designed with a modular construction, which allows for easy disassembly and reassembly. This can be particularly useful for businesses that need to reconfigure their systems or make changes to their layout. By using push-to-connect fittings, businesses can make these changes quickly and easily, without the need for specialized tools or equipment.

Finally, push-to-connect fittings can also help businesses save money by reducing the risk of leaks and other failures. These fittings are designed to provide a secure, leak-free connection, which can help to prevent costly downtime and repairs. By reducing the risk of leaks and other failures, businesses can avoid the costs associated with lost productivity, damaged equipment, and emergency repairs.

In conclusion, push-to-connect fittings are a cost-effective choice for businesses due to their ease of installation, reliability, and durability. By choosing these fittings, businesses can save money on installation and maintenance costs, reduce the need for additional components, simplify system changes, and reduce the risk of leaks and other failures.

Common Applications of Push-to-Connect Fittings

Push-to-connect fittings are used in a wide range of applications across various industries. Here are some of the most common applications for push-to-connect fittings:

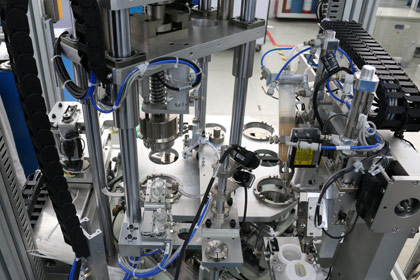

- Manufacturing: Push-to-connect fittings are commonly used in manufacturing applications, such as in assembly lines and conveyor systems. These fittings are ideal for these applications because they can be installed quickly and easily, and they provide a secure, leak-free connection that helps to prevent downtime and production delays.

- Automotive: Push-to-connect fittings are also commonly used in automotive applications, such as in fuel and brake systems. These fittings are a good choice for automotive applications because they are durable and resistant to corrosion, which helps to ensure reliable performance over time.

- HVAC Systems: Push-to-connect fittings are often used in HVAC systems, such as in air conditioning and refrigeration systems. These fittings are ideal for these applications because they can be installed quickly and easily, and they provide a secure, leak-free connection that helps to prevent costly refrigerant leaks.

Choosing the Right Push-to-Connect Fittings

When choosing push-to-connect fittings for a particular application, it is important to consider factors such as material, size, and pressure rating. Here are some tips for choosing the right push-to-connect fittings:

- Material: Push-to-connect fittings are typically made from materials such as brass, stainless steel, or plastic. The material you choose will depend on the specific application and the type of fluid or gas that will be flowing through the system.

- Size: Push-to-connect fittings come in a range of sizes, so it is important to choose the right size for your tubing or piping. Be sure to measure the outside diameter of your tubing or piping to ensure a proper fit.

- Pressure Rating: Push-to-connect fittings are rated for a specific pressure range, so it is important to choose a fitting that can handle the pressure of your system. Be sure to check the pressure rating of the fitting before making a purchase.

- Compatibility: It is important to ensure that the push-to-connect fittings you choose are compatible with the tubing or piping you will be using. Different types of tubing or piping may require different types of fittings, so be sure to check compatibility before making a purchase.

- Environment: Consider the environment in which the push-to-connect fittings will be used. For example, if the fittings will be exposed to extreme temperatures or harsh chemicals, it is important to choose fittings that are designed to withstand these conditions.

- Quality: Choose push-to-connect fittings from a reputable manufacturer that has a proven track record of quality and reliability. This will help to ensure that the fittings will perform as expected and provide long-lasting performance.

Choosing the right push-to-connect fittings is essential for ensuring reliable and cost-effective performance in a wide range of applications. By considering factors such as material, size, pressure rating, compatibility, environment, and quality, businesses and industries can choose the right fittings for their specific needs, and enjoy the benefits of reliable performance and cost savings over time.

Manufacturer for Push-to-connect fittings

Zhejiang Ideal-Bell Technolgoy Co., LTD

Website: idealbelltechnology.com

Ideal-bell is one of the leading Pneumatic fittings manufacturer in China, which specializing in manufacturing and marketing of Plastic pneumatic fittings, All brass push in fittings, BSP brass fittings, 316L stainless steel fittings, Air tube etc.

Ideal-bell focus on producing pneumatic fittings for 15+ years, with ISO9001, CE, RoHS, REACH certifications etc. We provide you high quality products and VIP service.

Ideal-bell have a well team-conscious, the ability of communication and coordination, work hard, meticulous and patience can afford the pressure of the work. We are young, passionate, fun, experienced, helpful, when doing business with us, there is nothing you cannot rest assured.

Hope to work with you together!