Pneumatic push fittings are essential parts of pneumatic systems used in various industries. They are used to connect pneumatic components such as valves, cylinders, and hoses, allowing compressed air to flow through the system. These fittings are designed to provide a secure and leak-free connection while being easy to install and maintain. In this article, we will discuss all you need to know about pneumatic push-in fittings. You’ll have a better understanding of pneumatic push fittings and how they can improve the efficiency and effectiveness of your pneumatic system.

What are Pneumatic Fittings?

Pneumatic fittings are used to ensure a secure and leak-free connection between components, which is crucial for maintaining system efficiency and safety.

There are several types of pneumatic fittings, including push-in fittings, compression fittings, barb fittings, and quick-connect fittings. Each type of fitting has its unique characteristics and applications, making it crucial to understand their differences and advantages.

Push-in fittings, also known as push-to-connect fittings, are widely used in pneumatic systems due to their ease of installation and maintenance. Compression fittings, on the other hand, require more effort and time to install but offer higher pressure ratings and are suitable for high-pressure applications. Barb fittings are often used in low-pressure applications and are ideal for connecting flexible tubing. Quick-connect fittings, also known as snap-in fittings, are designed to allow for fast and easy connections and disconnections between components.

Understanding the different types of pneumatic fittings and their applications is crucial for selecting the appropriate fitting for your specific application. In the following sections, we will focus on push-in fittings and explore how they work, their advantages and disadvantages, and common types of push-in fittings.

What are Pneumatic Push Fittings?

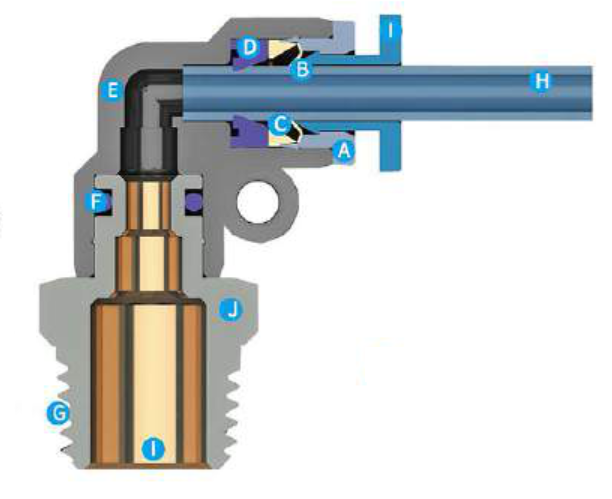

Pneumatic push fittings, also known as push-to-connect fittings, are a type of pneumatic fitting designed to allow for quick and easy connections between components in a pneumatic system. Push fittings are constructed of three primary components: the body, the release collar, and the sealing ring.

To connect a push fitting, the tube is simply inserted into the fitting body, and the release collar is pressed down firmly to secure the tube in place. The release collar can be easily pulled back to remove the tube from the fitting body. This simple and efficient connection mechanism makes push fittings ideal for applications where frequent maintenance and reconfiguration are required.

Push fittings are available in various configurations, including straight connectors, elbow connectors, tee connectors, and Y connectors, each designed to meet specific application requirements. Straight connectors are used to connect two tubes in a straight line, while elbow connectors allow for a 90-degree turn in the tubing. Tee connectors are used to connect three tubes in a T shape, and Y connectors are used to connect two tubes into a Y shape.

Advantages of Pneumatic Push Fittings

While pneumatic push fittings offer numerous advantages

Easy installation: Push fittings can be installed quickly and easily without the need for special tools or equipment, reducing installation time and labor costs.

Reusability: Push fittings can be disconnected and reused multiple times, making them a cost-effective solution for applications that require frequent maintenance or reconfiguration.

Leak-free connections: Push fittings provide a secure and leak-free connection, ensuring the efficiency and safety of pneumatic systems.

Versatility: Push fittings are available in various configurations, making them suitable for a wide range of applications.

How to Choosing the Right Pneumatic Fitting for Your Application?

Choosing the right pneumatic fitting for your application involves considering several factors. Here are some of the key factors to keep in mind:

- Press rating of your equipment

- The required temperature range of your machinery and system

- Tube size and material you will use

- Thread type and size of fittings you need

- Flow rate of fitting

- Environment and application

- Material compatibility with your system

- Easy of installation

- Maintenance requirements

The details refer to: https://idealbelltechnology.com/choosing-pneumatic-fitting/

How to Use Pneumatic Push Fittings?

Using pneumatic push fittings is a straightforward process. Here’s a step-by-step guide on how to use them:

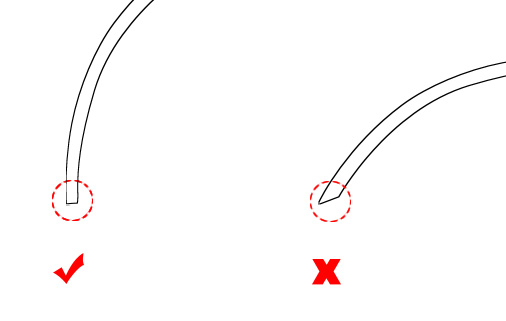

1. Cut the tubing to the desired length. Ensure that the tubing end is clean and free of debris.

2. Push the tubing into the fitting body until it reaches the sealing ring. Hold the tubing in place and press down on the release collar until it clicks into place.

3. To remove the tubing, press down on the release collar and pull the tubing out of the fitting body.

It’s important to note that when using push fittings, it’s essential to use the correct size and type of tubing to ensure a secure and leak-free connection. Push fittings should also be checked regularly for any signs of damage or wear and replaced as needed.

What’s the application for pneumatic fittings?

Pneumatic fittings are used to various of industries, here are some industries.

1. Manufacturing and assembly: Pneumatic fittings are used extensively in automated manufacturing processes, such as assembly lines, packaging equipment, and robotics. They provide precise control of the air flow required to actuate and control pneumatic cylinders, valves, and other components.

2. Automotive and transportation: Pneumatic fittings are used in air brake systems on commercial trucks and buses, as well as in the suspension systems of trains and heavy machinery. In automotive assembly, pneumatic fittings are used to provide precise control of air flow in power tools and equipment.

3. Construction and mining: Pneumatic fittings are used in the operation of various construction and mining equipment, such as jackhammers, air compressors, and rock drills.

4. Agriculture and farming: Pneumatic fittings are used in agricultural equipment such as seed drills, harvesters, and grain storage systems. They provide reliable and precise control of the air flow required for the operation of various pneumatic components.

5. Aerospace and aviation: Pneumatic fittings are used in various aircraft systems, such as pneumatic actuators, landing gear systems, and cabin pressure control systems.

6. Marine and offshore: Pneumatic fittings are used in various marine systems, such as steering and propulsion systems, and in offshore oil and gas drilling and production equipment.

7. Food and beverage processing: Pneumatic fittings are used in food and beverage processing equipment, such as bottling and packaging machines, where they provide reliable and clean connections for compressed air and other gases.

8. Pharmaceutical and medical: Pneumatic fittings are used in various medical devices, such as ventilators, oxygen concentrators, and anesthesia machines. They provide a safe and reliable connection for the flow of medical gases.

9. Chemical and petrochemical: Pneumatic fittings are used in various chemical and petrochemical processing equipment, where they provide reliable and precise control of the air flow required for the operation of various pneumatic components.

10. Energy and utilities: Pneumatic fittings are used in various energy and utilities systems, such as gas pipelines, water treatment plants, and power generation equipment, where they provide reliable and precise control of the air flow required for the operation of various pneumatic components.