Introduction

Pneumatic tubing is a critical component in many industrial applications, used to transport gases and fluids to power machines and equipment. Choosing the correct size of pneumatic tubing is crucial for ensuring that the system operates efficiently, safely, and effectively. Selecting the wrong size of tubing can lead to issues such as reduced flow rate, increased pressure drop, and potential damage to the system.

The purpose of this article is to provide practical tips and advice for readers on how to determine the correct size of pneumatic tubing for their application. We will discuss the factors to consider when selecting the appropriate tubing size, how to calculate the correct size of tubing, and tips for choosing the right size of pneumatic tubing. Additionally, we will explore common applications of pneumatic tubing and fittings in industries such as manufacturing, automotive, medical, and food and beverage.

Understanding Pneumatic Tubing and Its Components

Pneumatic tubing is a type of tubing used to transport compressed air or gas in industrial applications. It is typically made of materials such as polyurethane, nylon, or polyethylene, and comes in a variety of sizes and shapes to fit different applications.

The purpose of pneumatic tubing is to provide a conduit for compressed air or gas to power machines and equipment. It is commonly used in manufacturing and assembly lines, automotive and aerospace industries, medical and pharmaceutical industries, and food and beverage processing.

There are several types of pneumatic tubing materials available, each with their own unique properties and benefits. For example, polyurethane tubing is flexible and resistant to abrasion, while nylon tubing is strong and durable. Polyethylene tubing is lightweight and resistant to chemicals.

Pneumatic fittings are components used to connect pneumatic tubing to other components in a system, such as valves, regulators, and actuators. They come in a variety of shapes and sizes to fit different applications, and can be made of materials such as brass, stainless steel, or plastic.

Some common types of pneumatic fittings include push-to-connect fittings, which allow for quick and easy installation without the need for tools, and compression fittings, which use a ferrule to secure the tubing to the fitting. Understanding the different types of pneumatic tubing and fittings is essential for choosing the correct size of tubing for your application.

Factors to Consider When Choosing the Correct Size of Pneumatic Tubing

When choosing the correct size of pneumatic tubing for your application, there are several factors to consider:

- Pressure requirements: The pressure requirements of the system will have a significant impact on the size of tubing needed. Higher pressures will require larger tubing to ensure proper flow and avoid damage to the system.

- Flow rate: The desired flow rate of the system will also impact the size of tubing needed. Larger tubing will allow for higher flow rates, while smaller tubing will restrict flow.

- Length of tubing: The length of tubing needed to connect the various components in the system will also impact the size of tubing needed. Longer lengths of tubing will require larger tubing to maintain proper flow.

- Temperature range: The temperature range of the system will also impact the size of tubing needed. Higher temperatures may require larger tubing to avoid damage to the system.

- Type of fluid or gas being transported: The type of fluid or gas being transported will also impact the size of tubing needed. Different fluids and gases have different properties, such as viscosity and density, which will impact the size of tubing needed to avoid flow restrictions and ensure proper operation.

Considering these factors when choosing the correct size of pneumatic tubing for your application is essential to ensure that the system operates efficiently, safely, and effectively.

Calculating the Correct Size of Pneumatic Tubing

Calculating the correct size of pneumatic tubing is essential for ensuring that the system operates efficiently and effectively. The following formula can be used to calculate the correct size of tubing based on the factors discussed in the previous section:

Tubing size = (0.026 x Q) / (P x L x T)

Where: Q = Flow rate in cubic feet per minute (CFM) P = Pressure in pounds per square inch (PSI) L = Length of tubing in feet T = Absolute temperature in degrees Rankine (°R)

An example calculation using this formula would be as follows:

Suppose we have a pneumatic system that requires a flow rate of 10 CFM, operates at a pressure of 100 PSI, has a tubing length of 50 feet, and a temperature range of 60-80°F. Using the formula above, we can calculate the correct size of tubing needed as follows:

Tubing size = (0.026 x 10) / (100 x 50 x 560) = 0.00000092 cubic feet

Based on this calculation, we would need pneumatic tubing with a diameter of approximately 0.38 inches to meet the requirements of our system.

It’s important to note that this formula provides an estimate of the correct tubing size and should be used as a guideline. Consulting with experts in the field and testing the system is always recommended to ensure proper operation. In the next section, we will discuss tips for choosing the right size of pneumatic tubing for your application.

Tips for Choosing the Right Size of Pneumatic Tubing

Choosing the right size of pneumatic tubing for your application can be a complex process. Here are some tips to help you make the best decision:

- Consider the future needs of the application: When selecting the size of tubing, it’s important to consider any potential future changes or expansions to the system. Choosing larger tubing than currently needed may allow for future growth without the need for costly modifications.

- Choose a reputable supplier: Selecting a reputable supplier with a proven track record of providing high-quality, reliable products can help ensure that you get the right size of tubing for your application. Look for suppliers with experience in your industry and positive customer reviews.

- Consult with experts in the field: Consulting with experts in the field, such as engineers or pneumatic system designers, can provide valuable insights into the best size of tubing for your application. They can help you navigate the complex factors involved in selecting the correct size of tubing and ensure that your system operates efficiently and effectively.

By following these tips, you can make an informed decision when selecting the correct size of pneumatic tubing for your application

Common Applications of Pneumatic Tubing and Fittings

Pneumatic tubing and fittings are used in a wide range of industrial applications. Here are some common applications where they are used:

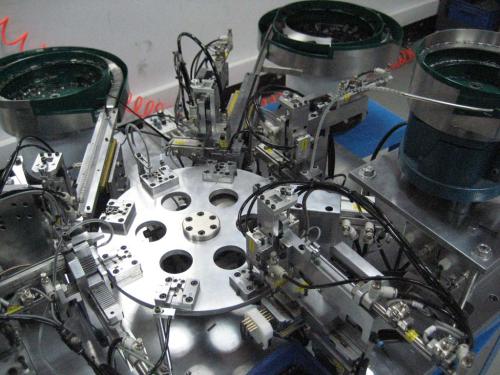

- Manufacturing and assembly lines: Pneumatic tubing and fittings are commonly used in manufacturing and assembly lines to power machines and equipment, such as conveyor belts, robotic arms, and pneumatic cylinders.

- Automotive industry: Pneumatic tubing and fittings are used in the automotive industry to power pneumatic tools, such as impact wrenches and air ratchets. They are also used in the assembly of vehicles, such as powering pneumatic presses and lifts.

- Medical and pharmaceutical industry: Pneumatic tubing and fittings are used in the medical and pharmaceutical industry for a variety of applications, such as powering medical equipment and tools, transporting fluids and gases, and controlling the flow of air in cleanrooms and sterile environments.

- Food and beverage industry: Pneumatic tubing and fittings are used in the food and beverage industry for applications such as transporting fluids and gases, powering pneumatic tools, and controlling the flow of air in cleanrooms and sterile environments.

In all of these industries, choosing the correct size of pneumatic tubing and fittings is essential for ensuring that the system operates efficiently, safely, and effectively. By understanding the factors involved in selecting the correct size of tubing and following the tips outlined in this article, you can make an informed decision and ensure that your system meets your needs.

Conclusion

Choosing the correct size of pneumatic tubing for your application is essential for ensuring that your system operates efficiently, safely, and effectively. In this article, we have discussed the factors involved in selecting the correct size of tubing, how to calculate the correct size of tubing, and tips for choosing the right size of pneumatic tubing. Additionally, we explored common applications of pneumatic tubing and fittings in industries such as manufacturing, automotive, medical, and food and beverage.

To summarize, when choosing the correct size of pneumatic tubing, it’s important to consider factors such as pressure requirements, flow rate, length of tubing, temperature range, and the type of fluid or gas being transported. Calculating the correct size of tubing can be done using a formula that takes these factors into account. Choosing the right size of tubing is essential for ensuring that your system operates efficiently, safely, and effectively.